Guide to IBC Totes: Types, Storage & Shipping, Tracking & Identification, and More

Intermediate Bulk Containers (IBCs) are used throughout the manufacturing and logistics world to transport large quantities of material in an efficient manner. These IBC totes were first used in 1992 as an alternative to the 200-liter (55-gallon) drums that were the primary bulk storage solution at the time. Since then, these containers quickly evolved to become the primary means of transportation and delivery for companies worldwide.

In this post, we’ll take an in-depth look into the design, maintenance, and transportation of intermediate bulk containers. As you’ll see, this guide will cover general information that is applicable to all IBC designs. Many IBC configurations are customized to meet the specific needs of different companies and use cases, and there are thousands of variations available in the market. You’ll also find some helpful guidelines and tips for storing and tracking these containers to ensure that reusable IBC totes are properly returned.

In this guide, we’ll discuss:

The International Organization for Standards (ISO) defines an intermediate bulk container as primary packaging that meets the following criteria:

These regulatory guidelines do not define a lower limit for size, but the ISO does note that IBCs smaller than 0.25 cubic meters (250 liters) are rare and may require specific tests to determine suitability. An IBC can be used as a returnable vessel and refilled multiple times or designed as a single-use container to be disposed of after transport of the enclosed material is completed. An IBC may also contain a liner that acts as a protective layer between the transported material and the outer wall of the IBC.

It should also be noted that these definitions pertain to IBCs that are used to transport non-hazardous materials. There are additional regulations for hazardous materials that are subject to additional scrutiny regarding the integrity and safety of the IBC totes. A good summary of these considerations can be found in 49 CFR 173.35 – Hazardous Materials in IBCs.

There are thousands of individual IBC designs, and we’ll break these down by reviewing the common types, sizes, and configurations that are common in the logistics industry. These descriptions of the various types of IBCs and other characteristics will help you understand what’s available in the market and how IBCs are used in different situations.

There are six major IBC container styles that are used to transport materials. These design types are often selected for each application based upon the specifications of the material to be transported and environmental factors.

IBC sizes range from 110 to 550 gallons with base dimensions that are roughly standardized to 45 inches long by 45 inches wide. This base size is set to align with the standard size of pallets, allowing these containers to be easily transported together with other logistics shipments. The height will vary with each container based on the specific IBC volume of construction. The most common sizes are 275 gallons and 330 gallons due to their even division into 55-gallon drums, which is the next standard size down for bulk material storage. Each IBC is also designed for forklift or pallet jack access with 2-way, 3-way, or 4-way mobility access.

As mentioned above, selecting an appropriate IBC often begins with a review of the safety and handling requirements for the material to be transported. In some cases, this means multiple IBC types could be suitable for a particular application. These are a few common considerations that manufacturers, distributors, and logistics partners use to finalize an IBC shipping plan, including:

Once an IBC configuration is chosen, it can often be used for several years as part of a routine supply chain loop. This is one of the main benefits of IBC containers versus smaller vessels as they allow a relatively large amount of material to be transported with fewer containers to manage.

The attachment of an IBC tote to other equipment for the purpose of filling or emptying the vessel is an important part of the transportation loop. Each IBC will come with a tap at the base of the container where the material can be transferred. Materials handlers can choose from several different fittings such as male cam, female cam, hosetails, NPT threads, and BSP threads. Before working with an IBC tote, it is helpful to review the design schematics to determine which fittings and adapters should be used for your particular applications.

You will find IBCs used in nearly all industries where large amounts of materials are transported. An IBC offers a convenient, safe, and reliable way to move quantities of material between manufacturing, warehouse, and end-user locations. Given the unique nature of each sector, you will often find several IBC configurations in service at any location. Some of the most active industries that use IBCs are:

The shipment of bulk materials using an IBC offers these organizations several benefits and economies of scale. By using fewer shipments at larger volumes, a company can achieve optimal quality control, operational costs, and transportation efficiency.

For several applications, such as the use of food ingredients, an IBC will be used as a returnable vessel and reused for multiple shipments. As reusable vessels, they must be cleaned after each use to ensure that the container is free of any contamination that could affect the quality of the next filling. There are two common methods of cleaning: clean-in-place (CIP) and clean-out-of-place (COP). This simply refers to whether the container is moved to another location to be cleaned or will have mobile equipment attached to complete the process.

In this handy guide, CSI Designs identifies several best practices for cleaning and maintaining the quality of IBC totes, including:

With proper care and regular inspections, IBC totes can be used continuously for several years. This helps reduce transportation and handling costs by extending the useful life of these vessels.

As mentioned above, most IBCs are designed to fit in the space occupied by a standard pallet and shipment. Working with these large containers requires a heightened sense of awareness and focus on safety. It’s important to always check that all hoses and attachments are disconnected from an IBC before movement and that the forks of a pallet jack or forklift are properly aligned underneath the vessel.

Storing IBCs can be done safely by following recommended best practices. Always consult the documentation and storage recommendations for any IBCs you use. The following guidelines can be used to offer some general insights into the IBC shipment and storage processes.

These are just a few of the many topics that must be considered when choosing an IBC shipment and storage plan. During any evaluation, safety should be the main priority, and regulations, best practices, safety data sheets (SDS), and manufacturer’s guidelines should all be consulted.

One of the biggest challenges in maintaining a fleet of IBC containers is tracking the location of each vessel. Many material suppliers will rent returnable IBCs to their customers to help improve the chances of them being returned. In many cases, the supplier must follow up with the customers on a regular basis to ensure that empty vessels are being returned in a timely manner. If returnable IBCs are lost in the process, it requires the manufacturer to invest in additional totes which can be costly over time.

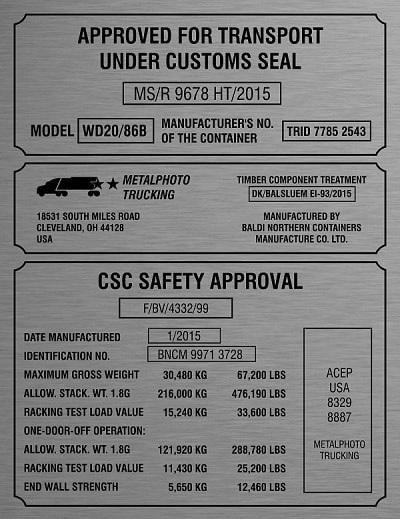

A best practice across industries involves the use of durable asset tags that include a unique barcode. Metalphoto® anodized aluminum is recognized by the National Association of Graphic and Product Identification Manufacturers (GPI) Industry Standards and Practices Manual as the most durable printed aluminum substrate available, making it an ideal choice for IBC labels to ensure readability throughout the useful lifespan of the vessel.

When connected to a centralized asset management platform, these IBC barcodes can be scanned prior to shipment and tracked in the system. This gives the IBC owner complete visibility into the number of containers present in warehouse locations, manufacturing sites, and customer facilities. These returnable tote barcode systems offer companies several benefits including:

An IBC is a valuable and often relatively expensive piece of equipment given its large size and durability. Properly tracking these IBC assets should be a priority and one of many ways that manufacturers and transportation partners can reduce logistics costs.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›