Every organization needs to identify, track, and manage the important assets that keep its operations running. Labeling or tagging these assets is a must to keep tabs on your most valuable or important property, and metal labeling is one of the most popular labeling solutions for manufacturers.

Different materials are best suited for different applications. Metal is more durable than plastic, which makes it an ideal substrate for demanding or harsh environments.

Even if you’ve already decided on metal labels for your factory or plant, you still need to understand the different types of metal labels available, as well as tips to help you get as much value out of your investment as possible.

This comprehensive guide will give you a detailed overview of metal labeling, its advantages over alternative materials, and best practices for using metal labels in your own business.

This guide will cover:

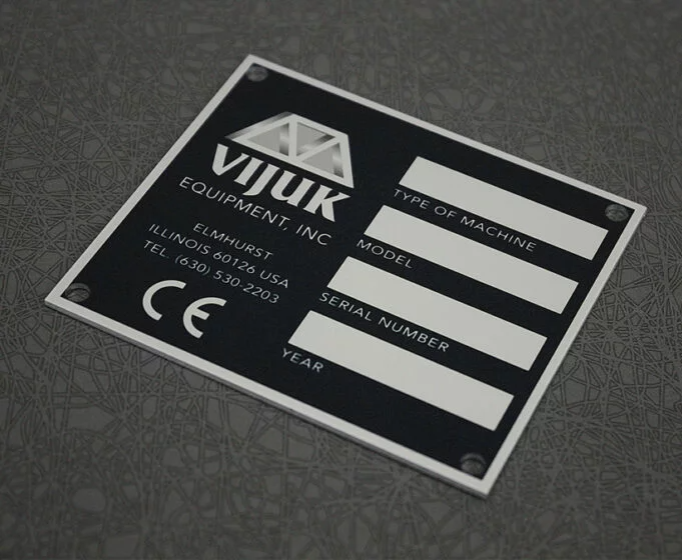

Metal labeling is a tagging method that businesses use to add durable labels to machinery or equipment. Sometimes this is for tracking assets, while other times it’s for safety, compliance, or educational purposes.

Metal labels are a widely-used method for identifying products, machinery, and equipment in industrial applications. Metal labels and tags display important safety and operational information, including:

While manufacturers can choose between many different substrate options for their labels, metal is the most popular option because it’s more durable. This means the information will be legible for a longer period of time, which helps manufacturers reduce costs while improving compliance.

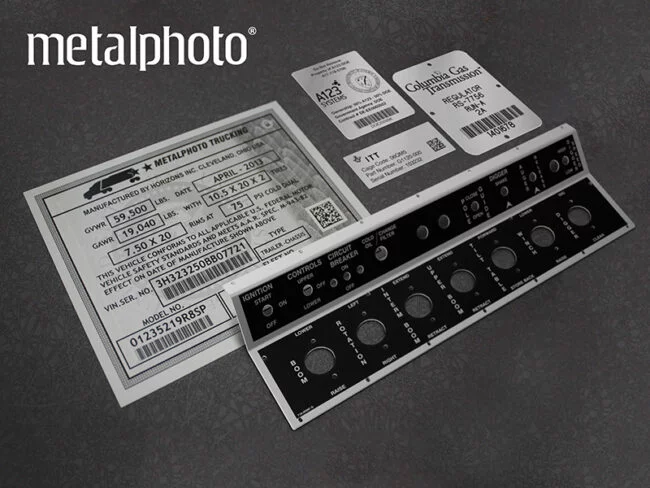

Depending on the substrate, metal labels come in a variety of sizes, shapes, colors, and thicknesses. MPC offers customizable metal labels and tags to meet a variety of different use cases in manufacturing.

To get the most value out of your metal labels, it’s important to choose the right substrate for your use case, budget, and needs. Choose from these popular options for either blank or pre-printed metal labels that last.

MPC’s Metalphoto® labels and tags are created from the most durable anodized aluminum substrate available. Graphics are sealed beneath a sapphire-hard anodic layer of aluminum, which creates an impenetrable surface. Our Metalphoto® labels and tags survive outdoors for over 20 years, even when exposed to extreme conditions.

Metalphoto® labels and tags can be purchased as a rigid or foil option. While still very durable, foil Metalphoto® labels are thin and flexible, which makes them easy to attach to textured or contoured surfaces, like pipes or valves. Rigid Metalphoto® labels come in various thicknesses for increased performance in the toughest conditions.

If you go with MPC’s metal labels, you can choose to either pre-print the labels so they arrive factory-ready, or you can choose blank tags to customize on-site.

Anodized aluminum labels and tags are a cost-effective alternative to Metalphoto®. While not as impenetrable as Metalphoto®, anodized aluminum is still very durable. This gives it excellent resistance to:

Anodized aluminum labels and tags can also be flexible or rigid, which will depend on the equipment or machinery you want to label.

Stainless steel is another strong metal that withstands corrosion, chemicals, and high heat. Different grades of stainless steel are suitable for a wide variety of applications.

MPC offers three types of stainless steel:

Brass labels and tags are a decorative yet durable option for manufacturing labels. Brass labels work well both inside and in harsh outdoor environments. This metal substrate offers excellent resistance to:

Brass is a low-friction metal that won’t generate sparks, so this metal substrate is a safer option for environments with electrical components, fire, or explosives.

Metal labels are durable and reliable, which makes them ideal for permanently identifying assets exposed to harsh weather conditions.

Rain, snow, ultraviolet radiation, and extreme temperatures can damage polyester or vinyl labels, which renders the identification useless in just a few months. But metal substrates are naturally resistant to environmental damage, impact damage and abrasion from dirt.

Because metal labels are stronger and more resilient, many organizations choose to invest in this permanent option for their products or equipment. However, some industries actually require their assets to have metal identification labels.

For example, the Department of Defense (DoD) mandates metal labels on machinery and other assets. The labels must also have specific identification numbers that are machine-readable.

While metal labels often have a higher initial cost than conventional materials, opting for metal can save money in the long run. Since metal labels are more durable than plastic, polyester, or paper, they have a longer expected lifetime. The information on metal labels remains easily readable and your labels will rarely need replacing.

Using metal for identification labels provides greater safety and security because it’s nearly impossible to remove or alter the information on these tags.

For manufacturers with a large number of expensive assets, permanent metal labels help you not only stay compliant with tamper-resistant labels, but also keep your manufacturing sites secure from sabotage.

Whether in a factory or a warehouse, manufacturers need to track assets between locations and departments. Opting for standardized metal labels helps you keep accurate inventory of your equipment, machinery, and other assets across all locations.

Metal labels are ideal for any industry that uses heavy equipment, including construction, military, aerospace, or transportation. Manufacturing is no different.

From property identification tags to hazardous material warning labels, manufacturers can use metal tags in a variety of ways. Every manufacturer is different, but manufacturers commonly use metal labels for these four use cases.

Every manufacturer converts raw materials into finished goods that they push through the supply chain. As you scale up production, it’s a good idea to generate labels for these goods — especially if you manufacture heavy machinery yourself.

Metal product identification tags allow manufacturers to track nearly every data point on a product, including its source materials, manufacturing date, employee activity, and much more. This makes it much easier for manufacturers to identify quality issues in their products or simplify the recall process if they find an issue with a product.

Photo by Marlene Leppänen via Pexels

Manufacturing is a dangerous job, and a single misstep can cause catastrophic injuries. Whether you’re required to follow certain safety regulations or you follow safety best practices out of an abundance of caution, proper labeling is a must to keep your employees safe.

Opting for paper safety labels will save money in the short term, but these labels aren’t built to last. Manufacturers run the risk of displaying unreadable labels, which can put you at risk of employee injuries and litigation.

Durable metal labels ensure your messaging will remain readable regardless of wear and tear, transportation mishaps, or extreme weather. Metalphoto®, anodized aluminum, and stainless steel labels are all suitable for industrial and heavy equipment applications.

Metal labels and tags are a crucial part of asset identification and tracking in the manufacturing industry. Paired with a solid asset tracking system, metal labels help manufacturers manage equipment, tools, and machinery across all their locations.

Scannable metal labels make it easy for employees to submit error-free reports about assets. It also speeds up check-in/check-out processes, leaving a paper trail that can help recover lost assets.

Unlike other materials, durable metal labels won’t fade or rub off with regular use. Manufacturers can enjoy greater peace of mind knowing that their asset labels can outlast the lifespan of the asset itself.

Factories and warehouses often contain valuable equipment that requires frequent maintenance. Metal equipment tags are ideal for tracking repairs and locating individual parts and pieces in a manufacturing plant.

Instead of conducting maintenance on a predetermined schedule, your team can use a maintenance tracking system for predictive maintenance. Your team will only service the equipment that needs maintenance, reducing costs and saving time.

Photo by Kateryna Babaieva from Pexels http

As a manufacturer, it’s important to optimize time, materials, and costs to be as competitive as possible. Metal labels are a solid investment, but even then, it’s important to get as much value from that investment as possible. Follow these tips to optimize your metal label ROI.

Always consider the environmental demands of the workplace before choosing a metal substrate for your labels. While most metals are very durable, some — like Metalphoto® — are especially suited for rugged environments.

Stainless steel is an ideal choice for food processing equipment, while brass might be best for applications where there are explosive risks present.

In addition to selecting the appropriate substrate, consider the surface of the asset you want to tag. For example, if the surface is curved or textured — such as a pipe or valve — a flexible foil equipment tag might be the best choice.

If you want to order blank metal labels and print them in-house, make sure you have enough label printers on hand at each location before you order the blanks. This will make it much easier to print and apply the labels as soon as they arrive at your facility.

Human-readable labels are important, but human error can slow down some processes. Instead, opt for metal labels that are both human- and machine-readable. This means every tag needs a text-based description for human users and either a QR or barcode for computers to read.

It’s easy to generate QR and barcodes from your asset tracking software. These codes make maintenance, asset tracking, and product identification much easier, as employees only need to scan the code.

Metal labeling gives manufacturers a durable, long-lasting identification solution that can withstand even the most challenging environments. Metal labels and tags are an excellent investment that helps you get maximum performance and value out of the expensive equipment that keeps your business running.

When it’s time to start labeling your equipment, assets, or tools, go with an experienced metal label provider like MPC.

MPC’s metal labels and tags are exceptionally durable, which makes them the preferred choice for indoor and outdoor applications. MPC manufactures both pre-printed and blank labels that meet stringent government and industry standards. Contact MPC today to find the best metal labels for your business.

Metal labels are beneficial because:

The right substrate depends on your budget and needs. These are some of the most popular metal substrates for manufacturers:

Yes. All metal labels are resistant to extreme heat and cold, corrosive chemicals, solvents, and abrasions from dirt or sand.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›