CSC (Convention for Safe Containers) sets forth important standards to ensure the safety of shipping containers through the global supply chain. Read on to learn about CSC plates, how they work, and best practices for manufacturers.

CSC, or the International Convention for Safe Containers, incorporates design requirements, minimum functionality requirements, and measurements of capacity, weight, and resistance to the forces containers are subjected to when  they ship by sea or on land within ships, trains, or trucks. The goal of CSC is to formalize international safety requirements for structural design and consistent inspection and maintenance of cargo containers. Overall, CSC ensures containers are built safely and inspected on a consistent basis to keep workers as safe as possible.

they ship by sea or on land within ships, trains, or trucks. The goal of CSC is to formalize international safety requirements for structural design and consistent inspection and maintenance of cargo containers. Overall, CSC ensures containers are built safely and inspected on a consistent basis to keep workers as safe as possible.

CSC is an international agreement dating to the 1972 International Convention for Safe Containers. Countries participating in CSC are contracting parties, and CSC is administered by contracting parties’ governments and organizations designated by them, such as the American Bureau of Shipping in the United States. CSC sets international standards in design-type approval and safety inspections so that containers operate globally under one set of safety regulations.

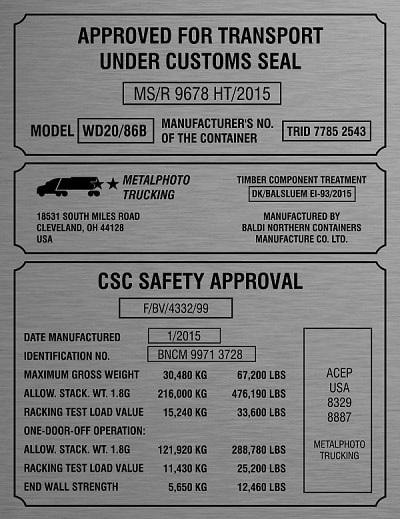

Once a container design meets all CSC and International Standardization Organization (ISO) standards, it is assigned a CSC number. The number appears on a safety approval plate, or CSC plate, that must be attached to the container. The CSC plate indicates that the container passed specific tests, met minimum standards for capacity, weight, and resistance to shipping forces, and has been issued a four-digit alpha code that identifies the container owners and its intended use.

CSC plates contain information that is vital to human safety. First, workers know that containers are approved when CSC plates are clearly visible. Second, they can review the required safety inspection portion of the plate to confirm that the container has been inspected within an acceptable time frame and is safe for use. The first safety examination must occur no more than five years after the date of production, and re-examinations must occur at least once every 30 months after that. Inspectors work to determine whether the container has sustained any damage that places a person in danger.

CSC plates contain different inspection information depending on the way in which the safety examinations are set up: periodic examination schemes require the plate displays the next examination date (NED) on the plate, while approved continuous examination program (ACEP) systems include off-hire and on-hire inspections for leased containers and in-service inspections for shipping line operating containers and do not have expiration dates. Containers in the ACEP program should display plates indicating the ACEP designation, the country that granted the ACEP, the year the approval was granted, and the ACEP registration number.

CSC plates are consolidated in nature and contain other information in addition to the CSC information such as TIR approval (confirmation that the container meets international transport under customs seal requirements); the owner’s serial number, name, and address; floor treatment TCT (confirmation the wood floor has been treated chemically to prevent infestation); and the manufacturer’s name and address.

Only entities authorized by contracting parties and the organizations designated by them may issue CSC plates. As for the United States, the U.S. Coast Guard stands as the top-level authority that authorizes other approval authorities to conduct CSC testing and certification.

Manufacturers should fasten CSC plates to each container they produce at the time it is manufactured. Typically, CSC plates are bolted to the exterior of the container’s left door. Each CSC plate must contain the following information either in French or English:

Additional information that typically is included on the CSC plate is the container owner’s name and contact information, the timber treatment information, and the container’s inspection date.

Other best practices for CSC plates include using those made of Metalphoto® anodized aluminum for durability and legibility. Shipping containers are exposed to salt spray from the ocean and roads in the winter, abrasion, sunlight, and other abrasive materials as they ship goods around the world. As such, their CSC plates must be able to withstand these harsh conditions without fading, corroding, or becoming illegible and posing a safety hazard or leading to regulatory fines for companies.

Metalphoto CSC plates have an expected service life of 20 years, making them a one-time expense compared to less-durable plates that may require periodic replacements. Their durability is enhanced by the fact that plate images are sealed beneath the sapphire-hard anodized layer that resists corrosion, sunlight degradation, abrasion, extreme temperatures, and chemical exposure.

Image via Flickr by techmsg

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›