With technology rapidly leaping to new frontiers, it truly is a boom time for chemical manufacturers and suppliers the world over. But, just because business is steadily rising and committed investors are continuing to lean in, doesn’t mean that the processing of these often noxious chemicals can be rushed. You will find pages upon pages of compliance guidelines for processing chemicals which must be followed perfectly, yet some forget that one of the key compliance issues doesn’t concern what’s in the container, but what’s labeled on its outside – the GHS, or Globally Harmonized System, label.

Back in 2012, the United Nations set a standard by implementing the GHS, which is a unified labeling classification system for chemicals. To ensure that the United States was following the guidelines to the letter, OSHA became the governing body of the GHS. The agency pulled this off by adding to its already-instated Hazard Communication Standard so that all of the elements of the GHS received extensive coverage. Ever since then, this safety system has been an integral part of the chemical-making, distributing, and supplying processes.

Whether you, yourself, are working in the chemicals business, or you have a chemical maker in your current supply chain, it’s important that you adopt, understand, and implement the GHS to the fullest.

In this guide, we’ll discuss:

What to Include in Your Written Hazard Communication Plan

Decades before the Globally Harmonized System was created, OSHA had its very own import/export chemical safety regulation program called the Hazard Communication Standard, or HazCom. As described above, when OSHA became the governing agency of the United States’ GHS, it merged many of the previously-instated standards from HazCom with the new components included in the global standard program.

One of these key standards is what is called the written hazard communication plan. Along with supplying each chemical container with the proper labeling, chemical-makers, laboratories, distributors, etc. are also required to create their own written hazard communication plans that can be easily referenced by employees, board members, third-party auditors, and, of course, OSHA, itself.

Here are the elements that must be displayed in each written hazard communication plan, via OSHA’s 1910.1200(e) regulation:

- An explanation of in-house GHS/HazCom compliance: this is meant to be a brief description that can include organizational elements, training procedures, and an account of responsible parties.

- A comprehensive list of hazardous chemicals: these product identifiers must be referenced on a corresponding data safety sheet and can be organized either by the facility or individual workspace for optimal clarification.

- An explanation of employee communication programs: this should include ways in which the employer communicates hazards for non-routine tasks. Example of these tasks includes cleaning protocol and unlabeled pipes in the workspace. Note: this explanation must also feature ways in which the employer (facility owner) plans to communicate these hazards to other workers, including contractors, in multi-employer workplaces.

- A copy must be made available upon request: a copy of the employer’s written hazard communication plan must be provided to employees, their designated representatives, and OSHA’s Assistant Secretary and Director on demand.

- A copy must be stored on-site: the written hazard communication plan must be stored at the primary work facility.

Though compiling a comprehensive chemical safety standard like the written hazard communication plan may seem like a laborious task, it’s required to ensure that all of the bases are covered in one, centralized document. It’s an important first step in achieving GHS/HazCom compliance, and one that should make the rest of the process much simpler.

The Required Components of a GHS Label

In addition to authoring a customized written hazard communication plan, OSHA also requires employers to label each and every one of their chemicals with a corresponding GHS label, as described in 1910.1200(f) of the HazCom/GHS standards.

Here are the components that all GHS labels must include:

- Product identifier: this must include the name of the product and/or the chemical name. Any other pertinent info can be added to the right of the manufacturer’s information.

- Signal word: a specific word that denotes the level of danger associated with the product.

- Hazard statements: a brief description of common hazards associated with the chemical or product. These statements should correspond with each and every chemical’s safety data sheet. These statements are indicated with a code that starts with the letter ‘H’.

- Pictograms: each label must include a pictogram that displays a universal visual of the hazards the product contains (more on this later).

- Precautionary statements: a brief explanation of how to administer first-aid if someone comes into contact with the hazardous chemical. This section should also include response, storage, and disposal precautions. These statements are indicated with a code that starts with the letter ‘P’.

- Chemical manufacturer/importer/responsible party information: the name, address, and telephone number must be indicated on the label.

It’s important to note that the above requirements do not apply to solid materials, including steel beams, metal castings, solid wood, plastic items, etc. In this case, the label only needs to be included in the initial shipment to the customer and needs not be shipped with any subsequent shipments, unless any of the chemical materials included in the solid change.

That said, if any liquid chemical product is in the same shipment as a solid, it must still adhere to all of the above labeling standards, no matter how many times the product is re-ordered.

Descriptions of Common GHS Pictograms

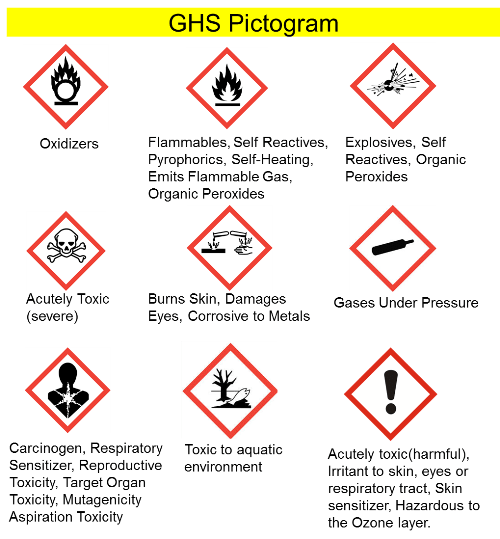

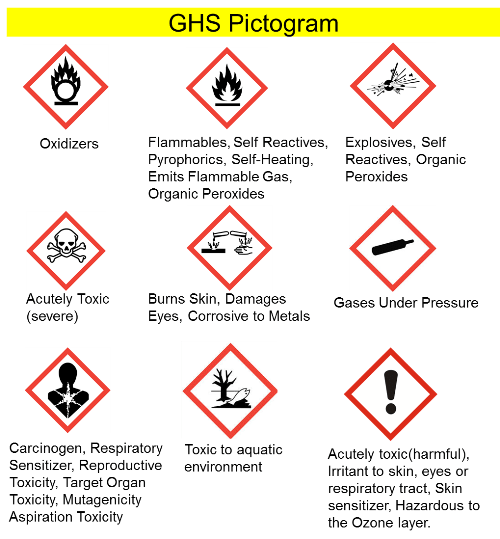

Pictograms featured on GHS labels are, arguably, one of the most important elements of the safety process. Currently, there are 9 separate GHS pictograms that are available for view on OSHA’s website. As the agency states, each of these 9 pictograms is meant to alert users about the chemicals to which they may be exposed.

Important: each pictogram must include the corresponding symbol on a white background surrounded by a framed red, diamond-shaped border. This design must be copied wholly to achieve the required standard.

Screenshot via Chem Safety PRO

Here is a description of each of the 9 GHS pictograms:

- Health Hazard: this pictogram includes a darkened silhouette of a person with a jagged, white overlay covering the chest. This symbol is meant to represent carcinogens, mutagenicity, reproductive toxicity, respiratory sensitizer, target organ toxicity, and aspiration toxicity.

- Flame: this pictogram includes a black and white flame illustration. This symbol is meant to represent flammables, pyrophorics, self-heating elements, flammable gas emissions, self-reactions, and organic peroxides.

- Exclamation Mark: this pictogram includes a solid, black exclamation mark. This symbol is meant to represent skin and eye irritants, skin sensitizers, acute toxicity, narcotic effects, respiratory tract irritants, and hazards to the ozone layer (not mandatory).

- Gas Cylinder: this pictogram includes a solid, black silhouette of a gas cylinder. This symbol is meant to represent gasses under pressure.

- Corrosion: this pictogram includes both a set of hands as well as a piece of metal being corroded by a liquid. This symbol is meant to represent skin corrosion/burns, eye damage, and metal corrosion.

- Exploding Bomb: this pictogram includes an illustrated image of a bomb mid-explosion. This symbol is meant to represent explosives, self-reactives, and organic peroxides.

- Flame Over Circle: this pictogram includes an illustrated flame with a circle sitting under it. This symbol is meant to represent oxidizers.

- Environment (not mandatory): this pictogram includes a nature-inspired illustration. This symbol is meant to represent aquatic toxicity.

- Skull and Crossbones: this pictogram includes a black and white outline of a skull and crossbones. This symbol is meant to represent acute toxicity (exposure to the material can lead to fatalities).

GHS Label Design Specifics

Although it might seem as if OSHA’s GHS/HazCom requirements are stringent ones, surprisingly, there are few requirements in regards to label design. This means that the employer is free to order and/or design their GHS labels with any company or using any material they choose.

Here are the label design specifics that must be followed, according to OSHA:

- All information must be entirely legible

- All printed information must be written in English

- All printed information can include other languages in addition to English, if necessary

- The label must be large and prominently displayed on the outside of the container

- Must be revised within 6 months if the employer becomes aware of new information that could affect GHS/HazCom compliance

Metalphoto of Cincinnati’s photosensitive anodized aluminum custom labels or compliance tags are an ideal choice for long-lasting readability, even when the label is consistently exposed to sunlight, corrosion, abrasion, heat, extreme cold, and even exposure to chemicals. The labels also come equipped with a customized design that can be used to properly describe the container’s contents.

Primary vs. Secondary Container Labeling

We already know what the GHS label should include, but one of the regulations that is particularly confusing, at first glance, is the standard of primary and secondary container labeling. Primary and secondary container labeling is meant to differentiate the materials and designs of the containers, specifically, so that the labels are placed at the most strategic points possible.

Let’s take a look at primary container labeling first:

Primary Container Labeling:

- Primary containers constitute bags, barrels, bottles, boxes, cans, cylinders, and drums that are used to store chemicals, typically straight from the manufacturer.

- Primary containers must contain all of the label elements, including product identifiers, signal words, pictograms, hazard and precautionary statements, and responsible party information.

- The label can never be removed, altered, or defaced.

- If the label is accidentally removed or wear-and-tear makes it illegible over time, the exact same information must be re-printed.

Secondary Container Labeling:

- Generally speaking, secondary containers are much smaller than their primary counterparts. These containers include spray bottles, jugs, or jars. Many times, these containers hold chemical products that are have been transferred from the primary container.

- Secondary containers must display the same labels EXCEPT when 1) the transfer from primary to secondary is made by one individual or team during a single work shift, 2) the transfer is completed in a singular work area, and/or 3) the secondary container stays in one work area with the same worker.

More in-depth information concerning chemical container transfer can be found in OSHA’s Laboratory Safety Labeling and Transfer of Chemicals guide.

Safety Data Sheet Essentials

Safety data sheets have been a requirement of chemical manufacturer’s since HazCom’s conception, but it’s easy to leave them by the wayside when the labels are so prominently featured. Even so, safety data sheets are relatively straightforward once your operation makes a centralized template.

Here is what every data sheet should include, according to 1910.1200(g) in OSHA’s HazCom standards:

- Each chemical manufacturer or distributor must have a separate data sheet for every hazardous chemical they import, produce, or use.

- All safety data sheets must be written in English in addition to other applicable languages. The formatting of the sheets must include sections numbers and headings with the appropriate information organized under each heading. The headings are as follows: 1) Identification, 2) Hazards Identification, 3) Composition/information on ingredients, 4) First-Aid measures, 5) Fire-fighting measures, 6) Accidental release measures, 7) Handling and storage, 8) Exposure controls/personal protection, 9) Physical and chemical properties, 10) Stability and reactivity, 11) Toxicological information, 12) Ecological information, 13) Disposal considerations, 14) Transport information, 15) Regulatory information, and 16) Other important information, including date of preparation and last revisions.

- If no information is applicable for a particular subheading, the employer must indicate so.

In addition to preparing the safety data sheet, the manufacturer must either send a copy to the customer with or prior to the shipment. These regulations stand for all responsible parties, including manufacturers, suppliers, and distributors, as well as customers using the chemicals.

Additional Resources on GHS Labels and Compliance Requirements

For more information on GHS Labels and Compliance Requirements, visit the following resources: