What to Look for When Choosing Preventive Maintenance Labels

Cutting-edge business solutions have transformed the modern workplace, yet there is one old-school technology that remains as invaluable as ever: the preventative maintenance label.

There are several factors involved in choosing the right preventative maintenance label for your equipment, such as the label size, material and attachment method. All these factors must be carefully weighed before a final decision is made.

In this article:

Photo by Anastasia Shuraeva via Pexels

This humble label has helped countless workers from countless industries keep tabs on the status of their equipment. Who last performed a safety check on a particular machine? When is the next inspection due? Were any prior inspection intervals missed or skipped?

The right preventative maintenance label – sometimes known as a PM label – can clearly and easily convey this information.

Of course, not all PM labels are equal. Because of the diversity of equipment using these tags, the variety of options on the market is almost dizzying.

If you’re tasked with ordering your firm’s next batch of PM labels, don’t let this breadth of selection paralyze you into indecision. Pause, and check out our advice below, where we break down the important factors – including design, compliance, and customization – you’ll want to look for when label shopping.

Need some tips on how to make preventative maintenance easier? Check out the video below!

Wherever you work – be it a factory floor, medical trauma center, or a grocery store’s back room – the environment is likely going to take a toll on your label. A quality PM label must hold up in those conditions that might degrade ordinary cardstock or adhesive.

That’s where the breadth of PM label designs acts in your favor. Factors such as the size, material type, and attachment method are some of the most important specs to keep in mind, as these details can help indicate whether the option you’re considering is suitable for your needs. Here’s a closer look at some of these key specifications:

This might sound obvious, but PM labels come in a variety of sizes. Larger ones are great for their expansive writing area and easy visibility, but they may be too bulky for the equipment.

A cardboard baler might be the perfect candidate for a XL-sized label, but in many cases you’ll need something smaller – for example, a precision piece of portal medical equipment.

Before ordering anything, we suggest getting the dimensions of what you need to tag. If the label isn’t sized appropriately for the application, you’ll only increase frustrations among those who regularly use and rely on this equipment.

The type of machines requiring PM tags are exceptionally diverse, and you can find them working in just about any setting, from steam-filled engine rooms and frozen warehouses to sterile labs and outdoor worksites. To provide an effective solution for all these very different use cases, PM label manufacturers offer their products in a range of material types.

Common material options include Metalphoto® anodized aluminum, stainless steel, vinyl, and polyester.

Polyester or vinyl may be able to withstand some adverse environmental conditions, but for machinery and equipment in harsh environments, Metalphoto® anodized aluminum is the most durable label substrate available. Our Metalphoto® labels withstand conditions such as extreme heat, humidity, long term exposure to weather, UV and other outdoor conditions, as well as salt spray, abrasion, industrial solvents, and chemicals.

The best material for a PM label depends on your application. That’s why we carry a wide array of label materials – so you can choose the option that’s perfect for your needs.

How do you plan to attach a machine’s PM label? Many tags are adhesive, some have mechanical attachment options, and others might simply loop around an appropriate nub or protrusion on the equipment in question. The best option boils down to what is the most effective and least cumbersome solution.

For an adhesive label, you’ll need to consider the surface it’s being affixed to. Is it rough or resistant to adhesives? If so, you may need a high-tack or material-specific sticker to ensure it doesn’t come off between maintenance intervals or while the machine is in ordinary use.

You may also need a specialized adhesive to combat the environmental conditions as well, such as high exposure to moisture or UV rays. MPC’s preventive maintenance labels use a permanent pressure-sensitive adhesive that bonds securely to a variety of surfaces and/or holes for mechanical attachment.

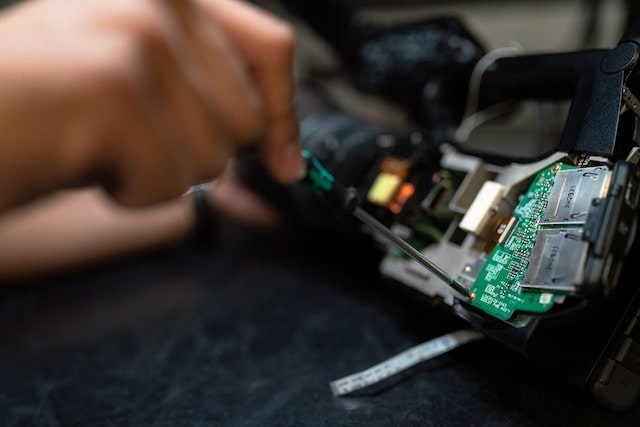

Photo by ThisisEngineering RAEng via Unsplash

Many preventative maintenance label manufacturers offer the chance to customize your label. There are several benefits to this, not the least being that a preventive maintenance label with your company logo proves you pay attention to the smallest details.

That said, altering the design or color scheme of a PM label can also have more practical benefits, such as:

It’s great to see your logo on a preventive maintenance label, but you may be able to play with the design in other ways as well. For example, you could incorporate additional relevant information that equipment operators or maintenance techs might need or want to know.

And if you work in a highly specialized field under stringent oversight, customization options can help you adapt a more generic design to the specific needs of your application.

From project trackers to stoplights, colors can silently and instantly communicate important information, even to untrained eyes. If you’re using a variety of PM labels throughout your operation, and you want these labels to correspond with different metrics – such as urgency levels or service intervals – color-coding is a great solution.

By ordering a custom batch of preventive maintenance labels in the colors you need, you can enhance what and how they communicate with your staff. If you’re looking for easy ways to further bolster your preventative maintenance strategy, this is a great place to start.

Different industries are subject to different laws and regulations, so ensuring that your operation is compliant with all relevant statutes is a critical consideration when choosing labels.

The extent to which this is relevant varies by industry, but specialized, highly scrutinized fields like aerospace and healthcare should be particularly careful in this regard.

Globally Harmonized System standards, for instance, include rules for labeling hazardous chemicals. For companies subject to the GHS framework, these guidelines may influence their PM labeling strategy.

Of course, there’s also overarching governance systems that all companies will want to adhere to. This includes the Occupational Safety and Health Administration (OSHA), which has established both widely applicable and industry-specific preventative maintenance procedures. You’ll want to make sure you follow these rules closely to ensure full OSHA compliance.

Photo by Andrea Piacquadio via Pexels

If there’s one thing to remember about preventative maintenance labels, it’s this: these labels are designed to keep equipment users informed, maintenance plans on track, and regulators happy.

When shopping for a PM label, choose one that checks all those boxes, but also ensure that it can withstand the environment it will be subject to. MPC’s experts can help you assess your application’s requirements, compare suitable material options, and select the best preventive maintenance labels for your needs.

By taking some time to find the right option for your needs, these small but mighty labels can help you get a head start on your maintenance strategy. Get in touch with MPC today to request a free Nameplate, Front Panel, Label & Tag Evaluation Kit.

There are essentially three types of preventative maintenance:

Depending on your situation, it might be an inconvenience to perform preventative maintenance on your equipment. After all, it can be costly to stop the use of particular equipment, especially if it’s vital to your operations.

However, consider what might happen if that equipment fails completely; not only could your operations come to a halt, but the repair could be more costly and time-consuming than if you’d performed preventative maintenance at the proper time. Still not convinced? You can read more about unlocking the value of preventative maintenance here.

Besides the obvious issues related to equipment downtime, there are several other potential disadvantages of preventative maintenance. There are upfront costs involved; since the right parts need to be on hand at the right time, these will need to be bought in advance.

An adequate number of maintenance staff must also be available, and if the maintenance is not planned correctly, equipment can be overly maintained, leading to detrimental side-effects.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›