What is the Variable Frequency Drive (VFD), How Does It Work, and Why Use It in Commercial HVAC Units?

A Variable Frequency Drive (VFD) is a motor controller commonly used for three-phase motors. Other names for Variable Frequency Drive include:

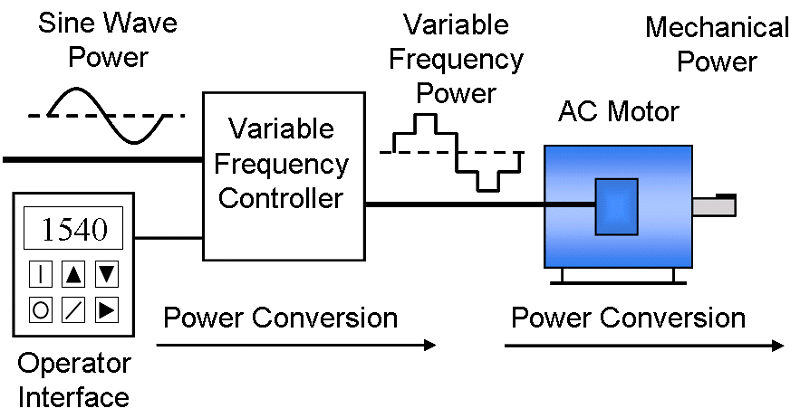

What makes VFDs unique is that they vary the frequency and voltage given to the electric motor based on its electrical and speed requirements, which helps to reduce energy usage and, in turn, lower operational costs. They’re equipped with control panels and durable graphic overlays, such as Metalphoto® Overlays and Anodized Aluminum Overlays, which offer resistance to extreme temperatures, UV, abrasion, chemicals, and solvents to remain readable even under harsh operating conditions. Durable data plates provide specifications and important operating details, such as safety warnings and equipment data.

In most cases, commercial HVAC systems need powerful motors like the three-phase motor. These are more efficient than single-phase motors since it uses less current (even when larger motors are used).

Let’s take a closer look at how VFDs work.

“VFD System” by C J Cowie at the English language Wikipedia is licensed under CC BY-SA 3.0

Let’s say you have a commercial HVAC system that doesn’t require the motor to operate at full speed. What controls the speed of a motor (RPMs) is frequency, or hertz. (These specifications are found on the equipment’s nameplate.) The higher the RPM, the faster the frequency. Since the HVAC system doesn’t require full speed, the VFD will lower the frequency and voltage so that it matches the electric motor’s load.

As the needs of the motor change, the VFD automatically increases or decreases the motor speed. The VFD waits for the signal from a controller and then responds to ensure the right amount of heating and cooling is supplied. The most common frequency adjustment range in HVAC systems is between 10 and 60Hz AC.

As for the setup, VFDs are wired in a series between the motor and the main power source. There’s also a bypass switch to prevent interruption of the HVAC’s operation (in the event the VFD requires maintenance).

There are several reasons why Variable Frequency Drives are excellent for commercial HVAC systems. Let’s take a look at the benefits.

Lower energy consumption (and therefore lower energy costs) is one of the reasons VFDs attract commercial property owners and HVAC professionals. It’s ideal to use one if you’re installing a system that doesn’t run at full speed.

The VFD is capable of adjusting the motor’s speed to match the load requirement. To date, there are no other methods you can use for AC electric motor control that can do the same. Now, it’s essential to note that electric motor systems consume over 65% of the power. By installing a VFD, you can lower the consumption by an impressive 70%.

At the same time, you’re also improving product quality and lowering production costs. And let’s not forget the tax incentives, utility rebates, and ROI you can witness within six months of installation. In other words, more money in your pocket.

Here’s an example:

When airflow needs decrease, the VFD consumes less energy. So if an HVAC unit needs 50% airflow, the VFD will consume 21% full airflow energy (compared to 65% for an inlet vane control and 87% for an outlet damper control).

The efficiency of HVAC systems will make it easier to operate machinery, such as conveyors and belts. No more jerking during startup or other costly mistakes that can slow down production.

Plus, it’s easier to control the settings as needed.

VFDs help to optimize motor application speed, which, in turn, helps equipment last longer and reduces maintenance requirements. The VFD offers protection to the motor because it controls the frequency and voltage, which can provide phase protection and prevent:

Screenshot via ControlDesign.com

Each time you start a load, you won’t have to worry about the motor or driven load being subjected to an “instant shock” common with across the line starting. This is also known as high in-rush current. When you turn on a standard motor, it draws in a large amount of current in a short period. The problem is that the spike can cause damage by overloading certain circuits. To avoid this, you can use a VFD, which allows the motor to start slower and smoothly, preventing wear to the belt, bearing, and gear. It’s also possible to reduce or remove water hammer since the acceleration and deceleration cycles run smoothly.

There’s monitoring for Variable Frequency Drives, which enables you to see the performance of HVAC systems. If there are any potential problems, you can detect and resolve them quickly before they turn into a significant problem. Preventive maintenance is key to keeping HVAC systems in excellent condition.

With all the benefits Variable Frequency Drives offer, it’s clear to see why they should be implemented in commercial HVAC applications. By integrating VFDs, property owners can save money and boost ROI – a definite win-win.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›