Boat manufacturing requires oversight of a number of technical areas that must come together to make a well-designed and safe recreational craft. While federal laws provide guidance over basic safety protocols such as life jackets and fire extinguishers, most manufacturing requirements themselves are managed within the industry.

The American Boat & Yacht Council (ABYC) was founded in 1954 as a non-profit to oversee the creation and management of industry-wide boat manufacturing standards for design, construction, maintenance, and repair. In addition to establishing these industry standards, ABYC also helps develop voluntary global safety recommendations that are frequently adopted both in the U.S. and many places abroad. Today, ABYC standards are used in certifications and boat inspections. They’re also referenced in relevant legal proceedings.

The ABYC safety standards apply to all major boat systems and are contained in the Standards and Technical Information Reports for Small Craft. ABYC has a team of over 400 volunteer marine experts assigned to 16 Project Technical Committees (PTCs) who annually review the standards and release updates.

Major industry groups are involved, including the U.S. Coast Guard, ISO, and numerous trade and private organizations. The standards themselves have been designed as voluntary with the responsibility being on the manufacturers to ensure that they are constructing their craft to the highest standards for safety. That being said, more and more organizations are adopting the standards and their framework so that all internal repair, maintenance, and construction of the vessels are as safe as possible.

ABYC does not certify boats themselves, and there is no inspection program for reviewing the work of manufacturers. As mentioned above, it is up to the manufacturer of the vessel to ensure that all of the established ABYC standards are adequately followed. The primary way that ABYC assists the industry in achieving adherence to the standards is by providing training and certification for technicians and engineers. Their certification program was developed with NOCTI (National Occupational Competency Testing Institute) which has helped the program maintain high standards, as well as international recognition. ABYC offers the following certification programs:

With each program, there is the option to take a complete course or self-study, followed by a proctored exam. This provides flexibility based on the availability and requirements of the manufacturer’s staff. There are also two forms of certification designations available: advisor and technician. The advisor designation is intended for staff who do not physically work on boats, while the technician designation includes a focus on equipment installation, repair, and troubleshooting. Each of these designations has slightly different requirements for passing the certification examination, including a work requirement for technicians. All certifications are valid for 5 years after which there is a recertification program in place in order to validate the requirements through an exam.

Today, ABYC standards and certification are recognized by industry professionals and consumers throughout the U.S. and, to a growing extent, internationally. There are many benefits to constructing a boat to these standards, including greater owner safety and increased liability protection for the manufacturer. The ABYC standards are also so extensive that they cover the majority of boat manufacturing requirements implemented by many other countries. As a matter of fact, some countries have actually adopted ABYC standards directly into their own local requirements.

The United States also has the National Marine Manufacturers Association (NMMA), which provides certification for boats. Their requirements are in direct alignment to ABYC standards.

In the European Union, the Recreational Craft Directive (RCD) united individual standards from EU member countries into a single set of requirements. Throughout Europe, adherence to the standards is required by law and are very similar to ABYC standards with references to specific ISO documents, as well. For Australia and New Zealand, the latest local standards for electrical construction in boats (AS/NZS 3004.2:2008) were released in 2008 and are also heavily referenced from ABYC. In most of these instances, local compliance is also required by law.

Today, approximately 90% of active boats are constructed to ABYC standards, with broad adoption taking place across the industry. With its robust certification, review, and training programs, there is no doubt that ABYC will continue to be the leader in boat manufacturing safety. As developments in technology continue to drive improvements in how boats are made, it is comforting to know that such an extensive program exists that can provide continuous benefit for manufacturers, as well as consumers.

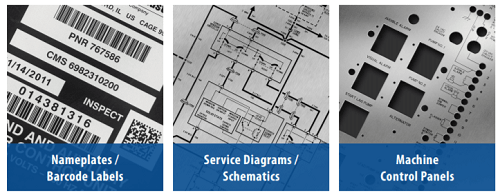

ABYC standards include specifications for marking and labeling various components and the use of nameplates to display information such as boat capacity. In marine environments, labels and nameplates must be able to withstand harsh environmental conditions such as abrasion, sunlight degradation, extreme temperatures, saltwater corrosion, and exposure to chemicals and solvents.

For more than 50 years, MPC’s Metalphoto® photosensitive anodized aluminum has been the material of choice for load charts, control panel faceplates, component labels, and other applications requiring identification labels that can withstand the harsh marine environment. Learn more about MPC’s nameplates and barcode label solutions for marine and shipbuilding applications.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›