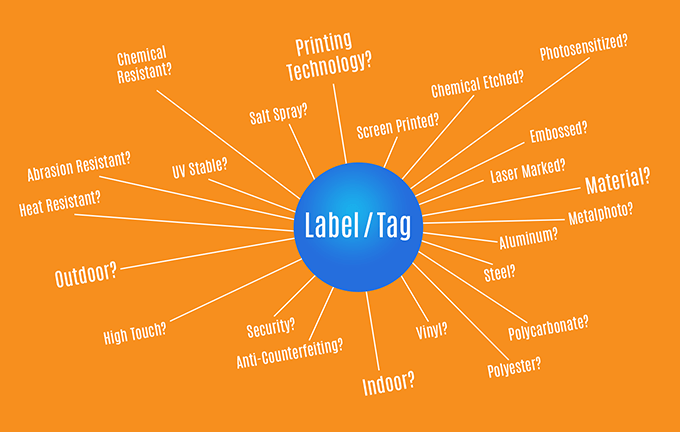

With so many nameplate and label material choices, it is easy to understand how some people end up buying an inferior material for their application – putting their company, themselves and their customers at risk.

MPC has developed a simple checklist of questions to answer before deciding which material to use for nameplates and labels for industrial and military products

Where will your product be used? In desert, marine, high-temperature or other environments? We have identified five performance factors to look for in a durable label or nameplate material. Be sure to check which of these your label must survive.

✓ Expected outdoor life: measured in years (1-3, 3-5 or 20+ years).

✓ Resistance to abrasion: measured in cycles on a tabor abrader (500, 1,000, 4,000 or 7,000+).

✓ Resistance to high temperatures: typically from proximity of the label to engines/pumps/generators, fire risk, etc.; measured in degrees resistant to (200°F, 400°F, 650°F or 1,200°F).

✓ Resistance to salt spray: from ocean or road salt environments; measured in days in a salt spray chamber (5, 15 or 30 days)

✓ Resistance to chemicals: such as Skydrol, diesel fuel, hydraulic fluid and MEK; measured in hours before degradation.

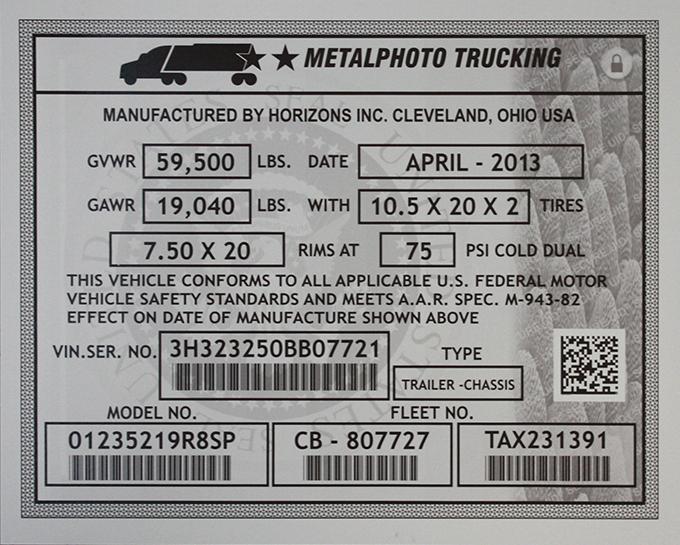

MPC offers a complete suite of metal and plastic materials including Metalphoto photosensitive anodized aluminum, one of the most durable nameplate and label materials available. Metalphoto’s durability comes from its image which is sealed inside of the anodized aluminum, providing outstanding resistance to corrosion, sunlight degradation, abrasion, extreme temperatures and chemical exposure.

What data is required on your label according to OSHA, ANSI, ISO or other standards? Is there additional data that might help your customer or service crews identify and maintain that items? Here are some of the questions you should ask:

✓ Will the data be static (same on every nameplate) or variable (serialized by plate)?

✓ Will the plate or label include barcodes or other machine readable (AIDC) marks?

✓ Do you need other graphic features such as micro-text for anti-counterfeit features or high-resolution maintenance schematics?

As a photographic medium, Metalphoto affords ultra-high resolution images and variable, serialized data making it ideal for barcode labels, custom sequential data and any amount of graphic detail required. Micro-text provides anti-counterfeit features that enable you and your customers to verify the authenticity of a part based its unique label.

Many OEMs and military organizations have standards for the types of materials used to label their parts. Aerospace OEMs often require labels to be made from Metalphoto foil because of its durability and light weight. U.S. and foreign military’s specify Metalphoto for UID barcode labels to keep track of assets. Be sure your label material meets the specifications of your customers. Here are some of the specifications that Metalphoto meets:

✓ MIL-STD-130N (Identification Marking of U.S. Military Property)

✓ MIL-DTL-15024F (Identification of Equipment)

✓ MIL-A-8625F (Anodic Coatings for Aluminum & Aluminum Alloys)

✓ MIL-PRF-61002 (Pressure-Sensitive Adhesive Labels for Barcoding)

✓ Federal Specification GGP-455B (Plates and Foils, Photosensitive Anodized Aluminum)

✓ A-A-50271 Class 2- Composition C (Department of Defense Commercial Item Description – Identification Plate)

✓ SAE AMS-QQ-A-250/1 (Federal Specification, Aluminum 1100 Plate and Sheet)

✓ ASTM B209-10 (Standard Specification for Aluminum and Aluminum Alloy Sheet and Plate)

✓ Standard UL 969 (Underwriters Laboratories – Marking and Labeling Systems)

✓ AAMI/CDV-1 ST79:2010/A2.06 (Steam Sterilization Validation for Medical Devices)

✓ RoHS/REACH (European Union Environmental Standards)

✓ ISO 6346/BIC VIN Tags (VIN Tags and CSC Safety Approval Plates for Trailers, Chassis and Intermodal Shipping Containers)

✓ Boeing Process Specification BAC5875

✓ Lockheed Martin, LMA-PN010, Fabrication of UID Nameplates for Aircraft Items

✓ BF Goodrich Aerospace, Data Systems Division, Specification SMT0022

✓ NASA Space Station Inventory Label Specification – SSP 50007

✓ Honeywell, Inc., Satellite Systems Operations, Metalphoto approved for use on Space Station, Memorandum A3-J024-M-9501786, Laboratory Case 161311

For more information on specifications, visit www.metalphoto.com.

Everything from size, thickness, and method of attachment needs to be considered, all based on your application and budget:

✓ Thickness: from 0.003” (.076mm) to 0.125” (3.175mm); Thinner foil labels (0.003” and 0.005” thick) will adhere to curved surfaces or sit inside recessed areas of your part. Thicker gauges from 0.020” up to 0.125” thick can be more resistant to damage from impact and abrasion.

✓ Size: does your item need to fit inside a recessed area or be legible from a distance; Metalphoto is available as small as 0.25”x0.25” and as large as 24”x40”, depending upon the application.

✓ Attachment: most suppliers will offer a variety of high-performance adhesives and mechanical attachment methods such as rivets or hang-ties.

Visit old.www.mpofcinci.com/samples for a free sample pack of nameplate or label materials.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›