Printed electronics are created using advanced printing technologies and novel materials to produce high-density electronic films. These components can then be used to create modern electronics such as RFID tags, flat panel displays, and sensors. As a rapidly expanding technology, the printed electronics market is expected to grow to over $20 billion by 2025 at a growth rate of over 20% per year. This represents a tremendous opportunity for manufacturers looking to integrate electronic components into their product designs.

Given the large number of applications where printed electronics can be used, there are several design options that are available in the market. In this post, we’ll take a look at some important considerations to weigh when choosing printed electronic components. In addition to material and performance characteristics, we’ll also review other considerations such as cost and customization. Carefully evaluating these points can help inform your printed electronics selection process.

The targeted application for a printed electronic component will define the necessary performance requirements. As electronic technology continues to evolve, we are likely to see thinner, faster, and higher-density components in the future. These are a few common applications for printed electronics:

Printed electronics are commonly used for applications that require functional thin-film components that are cost-effective, customizable, and flexible.

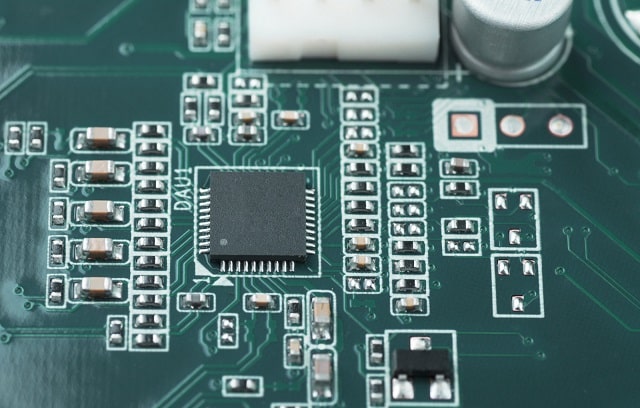

Several materials can be used as ink to fabricate printed electronics, including copper and silver. As a low-cost solution, copper can be used for low conductivity applications but does not offer the same performance as silver. Silver can be used to create large dimension prints with high conductivity, but it comes at a higher cost per volume. The conductivity of the ink is a major application decision as this will affect the circuit density, size, and substrate type that should be used for the final design.

The printing pattern is created to conform to the size and shape of the final printed electronic design. Each pattern will have been optimized to deliver ink material to the precise locations needed for device performance and integration with other hardware components. The sensitivity of the electronic surface can also be optimized through the choice of a printing pattern. Working with a trusted supplier can help you determine which pattern will work best for your specific application.

Electronic films can be printed on several different substrate materials. A few substrate examples are glass, paper, fabric, and plastics. Given the significant differences between these material types, the printing method and settings must be carefully chosen. Failing to choose the right combination of ink, substrate, printing method, and design can lead to a non-performing electronic component. There are two common printing technologies that are used to create printed electronics.

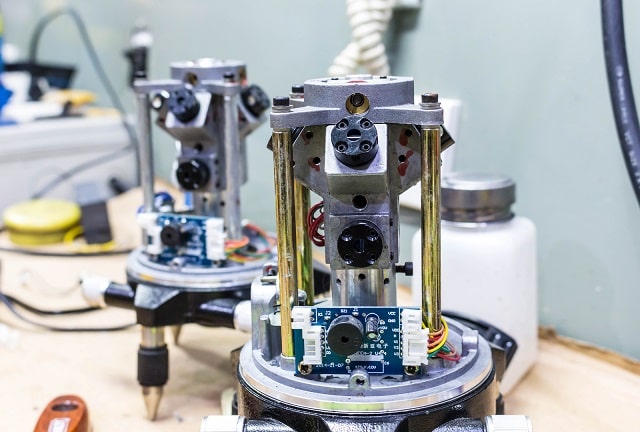

This method uses a stencil to create the printed ink design on the chosen substrate. In many ways, this technique is like applying solder to a printed circuit board. The printing process must be followed by a curing process where the materials are exposed to UV rays or heat.

The inkjet printing methods used for electronic components use advanced technologies to deliver ink material onto the substrate surface. There are four major technologies commonly used to create printed electronics. They are referred to as:

The delivery methods are highly technical, but the basic process involves moving ink from a storage well, creating droplets, and laying them on the substrate surface.

Choosing a printed electronic component should be done with a careful balance between cost and performance. Many aspects of the electronic printing process can be customized including ink selection, pattern, size, and printing method. For many advanced applications, off-the-shelf solutions may not be suitable, and your third-party supplier can often help you find the right materials and specifications for your project. Ultimately, it is the performance of the printed electronic component that will be most critical.

Choosing printed electronics can be challenging without a basic understanding of the technologies used to create them. The major topics outlined in this post were chosen to help inform your decision-making process as you narrow down your target applications and designs. Printed electronics represent a significant area of growth in the technology industry and will likely be found in a growing number of new products. The ability to integrate electronic components onto surfaces gives designers and manufacturers countless ways to connect technology with our everyday lives.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›