The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is a set of guidelines for identifying and classifying hazards associated with various substances. Most importantly, the GHS standardized this classification globally (as its name suggests), which allows for better collaboration and improved safety within the global supply chain. Here’s an overview of the essentials you should know about GHS.

The Globally Harmonized System of Classification and Labelling of Chemicals was developed by an international team of hazard communication experts to establish a standard set of rules for classifying hazards. GHS defines and classifies chemical product hazards and communicates health and safety information on labels and safety data sheets. GHS also establishes the format and content for labels and safety data sheets to be used globally.

The Globally Harmonized System of Classification and Labelling of Chemicals was necessary for resolving the various classification systems utilized around the world. Governments needed a standard system like GHS because of the expense involved in regulating and enforcing multiple classification and labeling systems, and companies needed a  standard system to save the costs of complying with those multiple systems. Government agencies and companies also needed a standard classification and labeling system to make it easier for workers to understand the hazards of the chemicals and products with which they work. Since the implementation of the Globally Harmonized System of Classification and Labelling of Chemicals, these organizations have realized several benefits including:

standard system to save the costs of complying with those multiple systems. Government agencies and companies also needed a standard classification and labeling system to make it easier for workers to understand the hazards of the chemicals and products with which they work. Since the implementation of the Globally Harmonized System of Classification and Labelling of Chemicals, these organizations have realized several benefits including:

The United Nations (UN) adopted the GHS in 2003. The GHS specifies criteria for classifying health, physical, and environmental hazards in addition to specifying the information that must be included on hazard chemical labels and safety data sheets. In 2012, the Occupational Safety and Health Administration (OSHA) revised its Hazard Communication Standard (HCS) to align with the GHS. As a result, U.S. employees gained the right to know which chemical hazards they were exposed to in addition to the right to understand them.

OSHA set deadlines for various steps toward full alignment with the GHS. By December 2013, employers must have trained employees in reading GHS formatted labels and safety data sheets. By June 2015, chemical manufacturers and distributors had to complete hazard reclassification and produce GHS-compliant labels and safety data sheets. Distributors also had an additional six months to complete shipping of old inventory by June 2015. By December 2015, distributors had to fully comply with GHS requirements, as the grace period for old inventory shipments came to an end. By June 1, 2016, OSHA expected full alignment with GHS. Employers must be in full compliance with the revised HCS, and their employees had to be completely trained in the new hazards and revisions to the workplace hazard communication program.

After OSHA aligned with the GHS, companies faced significant changes in hazard classification, labels, safety data sheets, and training practices. They also incurred additional expenses to reclassify chemicals, rewrite safety data sheets, train workers on the new hazards and GHS formats, and print labels in color. However, organizations realized savings by needing only to comply with one system of classification and labeling. One of the most significant benefits of aligning the HCS to the GHS was improved worker safety, as fewer peopled died or were injured annually as a result of working with chemicals and products featuring the new labels.

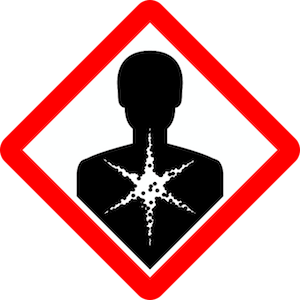

One of the most significant impacts of the Globally Harmonized System of Classification and Labelling of Chemicals is the change to hazardous  chemical labels. GHS labels must contain six pieces of information: the material supplier’s name, address, and telephone number; product identifier; signal word; hazard statements; precautionary statements; and pictograms. GHS labels are standardized and must contain specific information as assigned to each hazard category. Manufacturers and distributors first must classify a hazard and then communicate its corresponding signal word, hazard statements, precautionary statements, and pictograms.

chemical labels. GHS labels must contain six pieces of information: the material supplier’s name, address, and telephone number; product identifier; signal word; hazard statements; precautionary statements; and pictograms. GHS labels are standardized and must contain specific information as assigned to each hazard category. Manufacturers and distributors first must classify a hazard and then communicate its corresponding signal word, hazard statements, precautionary statements, and pictograms.

GHS pictograms are standardized symbols that quickly communicate the type(s) of hazards materials present to handlers. The pictograms must be framed within a red square frame set on point. The image is a black symbol on a white background. There are nine GHS pictograms in all: health hazard, flame, exclamation mark, gas cylinder, corrosion, exploding bomb, flame over circle, environment, and skull and crossbones. It is worth noting that the environment pictogram is not mandatory because OSHA does not regulate aquatic toxicity.

Images via Pixabay by hioahelsefag and 13smok

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›