Food Equipment Manufacturers’ Guide to FSMA Regulations and Compliance

No matter your revenue or company size, if you fall into the category of ‘food equipment manufacturer’ than you know just how important–and challenging – it can be to stay abreast of the current food safety standards, particularly the new FSMA regulations. The United States has one of the most stringent and progressive philosophies on consumer safety, so when it comes to keeping both its citizens as well as those around the world who purchase American-made, at their healthiest, food is the most scrutinized. In fact, Food Safety Magazine named the U.S. as having the world’s best food safety regulations and practices, right behind Canada.

Of course, living up to the standards that this country has set for its food companies concerns a number of industries in any given supply chain, but one of the most important is that of the food equipment manufacturers. Food processors can be as diligent in their own safety practices as possible, but if their specialized food equipment is not up to snuff, then their entire operations can be compromised.

To better understand how you, as a food equipment manufacturer, can ensure that you are keeping you, your customer, and the public safe via your specialized equipment, let’s take a closer look at the holy grail of standards – the FDA’s Food Safety Modernization Act.

In this guide, we’ll discuss:

The FSMA, otherwise known as the Food Safety Modernization Act, was first recognized back in January 2011 when then-President Obama made it a federal law. Since then, the FDA has spent the better part of the last decade solidifying and, now enforcing, what has become the most overarching food safety reform of the past 70 years.

For many both in and out of the food processing, distribution, and equipment manufacturing industries, FSMA is a law that has been a long time coming. Though it may make life more complex on those working behind-the-scenes, it provides a clear set of standards for all entities selling food and supplements for human consumption, either within or being imported into the U.S. The ever-intensifying glare of the media has shined a spotlight on the more than 3,000 Americans who die each year from foodborne illnesses, a fact that rightly puts even more pressure on all parties to put their best foot forward. An estimated 48 million people, or 1 in 6 Americans, gets sick from foodborne illnesses each year, while 128,000 are hospitalized. Globally, the figures are even more grim: 420,000 people worldwide die annually from foodborne illnesses; 125,000 of them are children under the age of 5.

Because food processors are now grappling with these strict requirements, it’s important that you understand what your customers are currently facing. Let’s take a look at the FDA’s FSMA guiding principles and how they might affect the way in which you do business:

Sanitation control is the name of the game when it comes to food processors and facilities reaching FSMA compliance. While there are certainly many steps to achieving this for your customers, it’s your responsibility to ensure that each and every surface can stay clean and is, more importantly, easy to clean.

Remember, the FDA’s FSMA calls for all pieces of equipment to be easily dismantled for regular sanitation. This means that your design components must be free from hollow areas, when possible, and must be rigorously engineered to bear constant disturbances.

How Processor Preventive Controls Plans Can Affect Your Business

One of the more fascinating aspects of FSMA is that it requires food processing facilities to provide a written preventative controls plan that cites any vulnerable areas in their processing system. The plan is meant to act as a proactive exercise that forces the processors to consider the hazards, preventative steps, and controls that might affect their food safety standards. Specifically, the FDA aims to focus these processors on food allergen and sanitation controls.

Of course, if the business does not feel confident that their equipment can be quickly and easily disassembled for regular cleaning, inspection, and sampling, then they will be forced to formally list this information.

If you don’t provide your processor customers with both the tools and the knowledge to know that they are delivering a consistently safe product, then you could be quickly identified as a “weak point” in their supply chain to both corporate decision-makers as well as influential third-party inspectors.

Seasoned compliance managers know that the key to building pieces of equipment that help their customers adhere to strict laws is by assessing all available guidelines. Let’s take a look at how two that pertain more directly to the food equipment manufacturer tie into the demands of the FSMA:

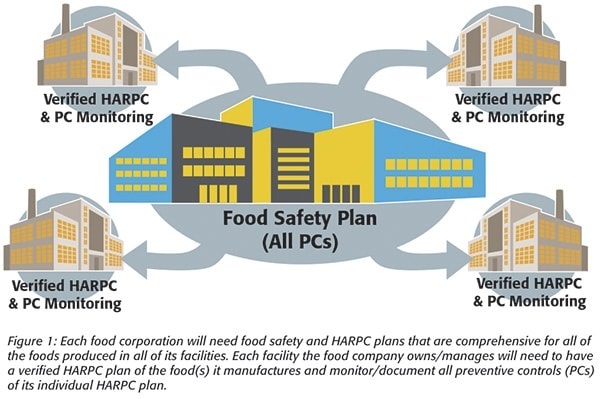

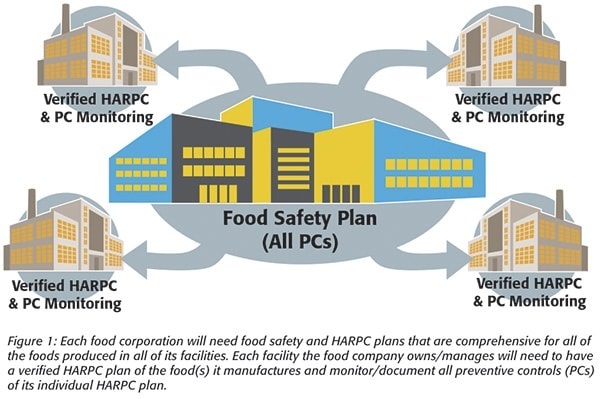

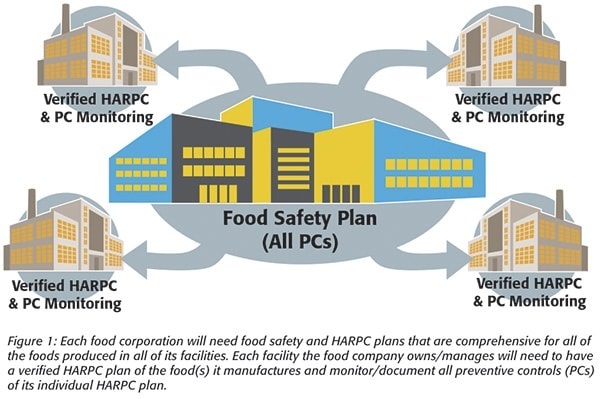

Screenshot via Food Safety Magazine

To engineer a piece of equipment that allows your processor customer to face the FSMA standards with certitude, you must first put yourself in their shoes. While your design team might invent a component that makes the product cheaper, small, more effective, etc., that won’t mean anything to your processor customer if they aren’t certain that it can be consistently sanitized and free from the perils of cross-contamination.

Let’s take a closer look at the questions processors must answer daily in regards to the FSMA preventive controls:

As you can see, the key to guaranteeing a safe, long-lasting piece of equipment that will adhere to various sub-sets of standards is to better acquaint yourself with the challenges of the processor.

What cannot be stressed enough is the fact that with food safety laws becoming more stringent by the decade, the most innovative food equipment must not just be efficient – it must be free from the variables that cause cross-contamination.

If you produce food conveyor belts, for instance, you will want to design with sanitation in mind. This means working with the processor to better understand the layout of their facility. Do they have a dedicated area with enough space to properly dismantle and clean the conveyor belt? Are there any particularly pronounced nooks and crannies that make regular sanitation difficult? Has your piece of equipment been certified with a 3-A Sanitary Standards, Inc. seal? The last point may be a necessary step in ensuring that you, as a manufacturer, are upholding the promises that you are putting forth. Food equipment certification from the NSF ensures that your equipment meets the most stringent regulatory standards.

As a producer of food processing equipment, you know that your product is only effective when used correctly. Luckily, FSMA puts total control in the hands of the processor, meaning they are completely responsible for each component of their supply chain. But liability aside, it’s still in your best interest to confirm that the person in charge understands how every facet of their new equipment works.

This confirmation might come in different forms depending on the situation, from the creation of comprehensive training manuals to conducting training seminars. But, whatever your customer decides, these days, processors are hyper-focused on achieving total compliance; breaking the process down so that the necessary employees can operate and sanitize the equipment masterfully is key.

For more information on the specifics surrounding the FSMA guidelines and what they mean for your food equipment business, visit the following resources:

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›