Since its introduction in 2005, the U.S .Department of Defense’s Item Unique Identification (IUID) program has grown significantly. Millions of assets have been tagged and registered and several NATO allies have adopted the IUID barcode platform.

IUID, as outlined by MIL-STD-130, does little to define the types of label materials to use in each military operating environment. MIL-STD-130 only references durability in as far as the label must be “as permanent as the normal life expectancy of the item and be capable of withstanding the environmental tests and cleaning procedures specified for the item to which it is affixed”.

Because label longevity is critical to IUID (the value of the program collapses when labels are illegible or detach), the Naval Surface Warfare Center (NSWC), Corona Division IUID Center conducted a study of commercially available label materials (the IUID Environmental Survivability Testing Report).

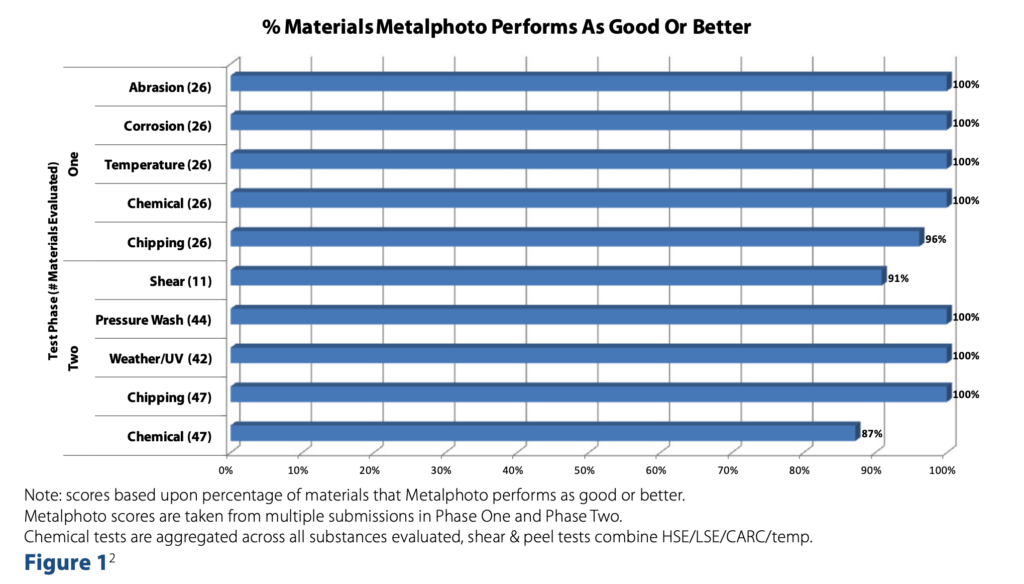

The Report offers an unbiased, governmentsponsored comparison of label durability in order to help project managers identify the best label material for their operating environment(s). This paper outlines the results of the Report as they pertain to Metalphoto®, the material that earned more high scores than any other evaluated (Figure 1).

The Item Unique Identification (IUID) Environmental Survivability Testing Report was conducted in two phases: the first published in August 2011 and the second in September 2012. The second phase was implemented in order to incorporate several new tests and label materials. In

particular, adhesion to CARC paint, elevated temperature adhesion, UV exposure, pressure washing and new chemical exposure tests were added in phase two. Across both phases 73 label materials were evaluated in 38 simulated operating environments (Figure 2).

The 73 materials were submitted by 18 companies. Submissions can be grouped into the following categories (Figure 3):

All submitted labels contained information about the material and a 2D data matrix barcode required for IUID. Labels were evaluated using a Microscan UID DPM Compliance verifier to the AIM-DPM-1-2006 standard. Using the verifier (vs. human observation) has the advantages of being

both objective (quantitative, measured by a machine) and the established military standard for an acceptable barcode mark under MIL-STD-130.

| Simulated Environments | Laboratory Test Conditions |

|---|---|

| Sunlight/Weather Exposure | Exposure to sunlight in California desert conditions for 6 months (Feb-Aug) |

| Abrasion | Taber Abraser, CS17 with 1kg wheel load as per ASTM D4060 |

| Chipping | 50 ft. gravel drop; modified ASTM D3170 and ASTM D2794 standard tests |

| Shear/Peel Strength | Labels were peeled (flexible materials) / sheared (rigid materials) at a set angle at a constant rate while measuring the force, modified ASTM D3167. Adhesion tests were performed on three surfaces: glass, polypropylene, and CARC, at room temperature and 110°F. |

| Temperature Exposure | Labels were exposed for one week to high temperatures (160°F±5°F) and cold temperatures (-40°F±5°F). Peel/shear tests were conducted at 24 hours, 72 hours and one week. |

| Pressure Washing | A 2 gallon per minute pressure washer limited to 1,200 pounds per square inch (psi) as required by US Marine Corps Technical Manual, TM 4795-OR/1A; total detachment or edge lifting was recorded. |

| Chemical Exposure | Immersion for 10±1 minutes and 7200±60 minutes (5 days±1 hr) as per MIL- STD-810 Method 504. Sixteen chemicals were evaluated. |

| Salt-Spray/Corrosion | MIL-STD-810 method 509.5 and ASTM B117. |

The 10 Metalphoto labels submitted varied by adhesive (3M 9485, 3M 9469, 3M 9672 LE and CARC adhesive), laminate (none vs. SandShield) and marking method (pre-print vs. YAG laser marked). It is important to keep in mind when considering Metalphoto that it can be customized with adhesives specifically suited to the bonded surface/ application or laminates that enhance its chemical or abrasion resistance. As a raw material (vs. a pre-adhesive applied system), Metalphoto can be configured into a variety of customized label systems to address variety of surface energies and overall applications.

| Material | # of Submissions | Base Material |

|---|---|---|

| Polymers (Polyesters, Acrylates, etc.) | 51 | Plastic |

| Photosensitive Anodized Aluminum (Metalphoto, BlackPlus) | 14 | Anodized Aluminum |

| Ceramic coated stainless steel | 2 | Steel |

| Direct part marked stainless steel | 1 | Steel |

| Coated anodized aluminum (DuraBlack) | 5 | Anodized Aluminum |

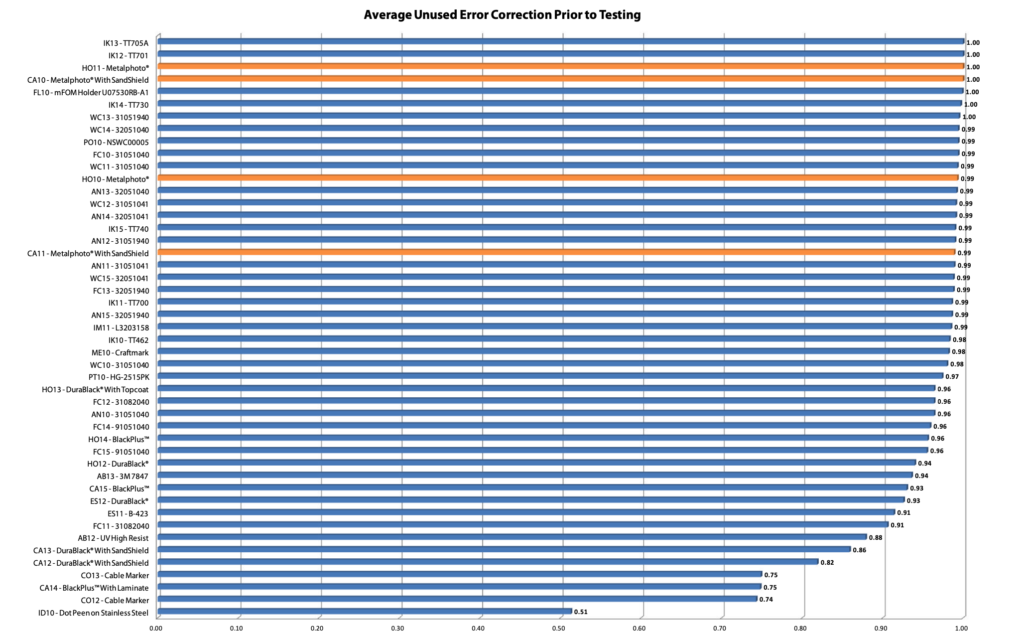

Prior to each tests, all labels were verified. Verification was used as a baseline for subsequent testing. In terms of pre-test verification, Metalphoto labels rose to the top due to the high-resolution capability of the material. Because Metalphoto is a photographic substrate, it is ideal for high-detail, small labels on small surfaces such as guns, sights and communication equipment. Additionally, Metalphoto’s resolution allows for micro print and

other anti-counterfeit measures to be incorporated into existing labels and nameplates (Figure 4).

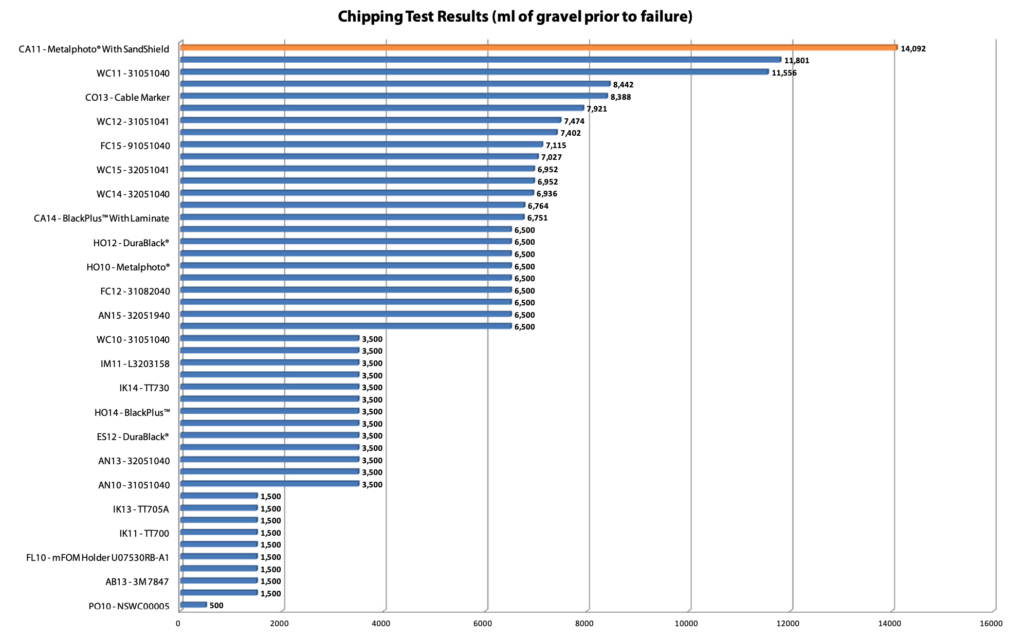

Labels were subject to a 50 foot drop (≈40 mph) of gravel in ever increasing amounts from 500 ml up. Labels were verified after each round and failure was the volume of gravel to reduce the UEC to zero. Most labels failed with 6,500 ml or less gravel. Plastic labels were most subject

to failure. However, a handful of labels stood out. In particular, Metalphoto with SandShield dominated the phase two results, surviving after 14,092 ml of gravel – 2,291 ml more than the next best material (Figure 5).

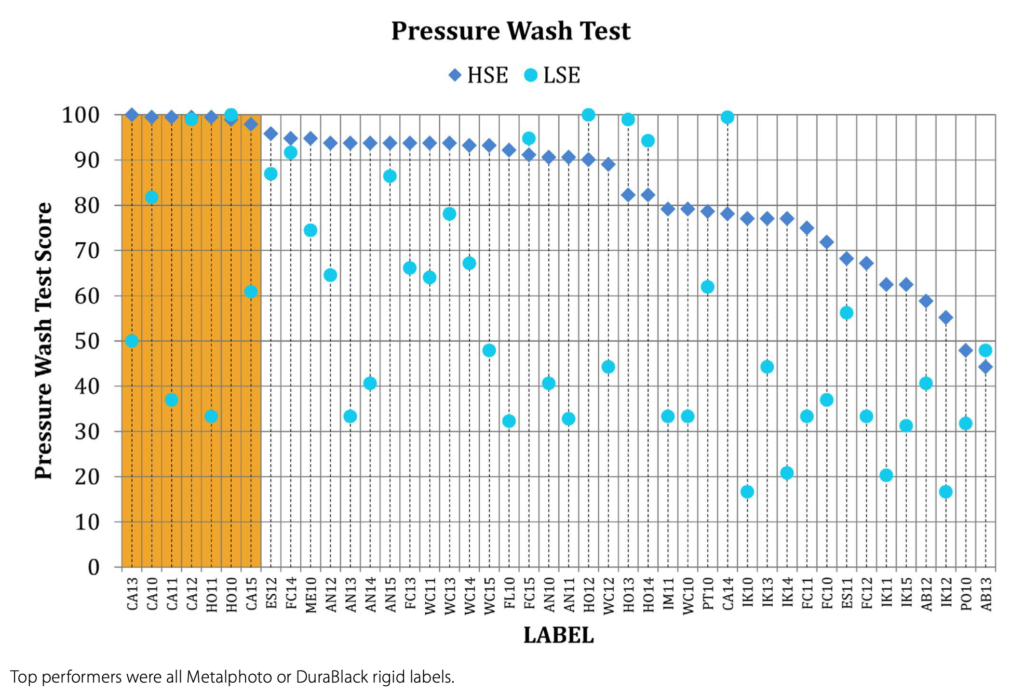

Rigid substrates like Metalphoto and DuraBlack stood up extremely well to pressure washing – across both of high surface energy (HSE) and low surface energy (LSE) surfaces. In fact, Metalphoto and DuraBlack rigid 0.020” labels with 3M 9485 adhesive scored better than any other material tested. According to the Report, “Rigid labels tended to perform better in pressure wash than flexible labels. Greater label thickness and label rigidity reduces the tendency of the label to start peeling.” (Figure 6)

All rigid 0.020” thick Metalphoto labels were tested with a shear test vs. the peel test conducted on the flexible plastic labels. As such performance can’t be compared because the test methods vary. That said Metalphoto labels exhibit 30-118 lbs/in of adhesion strength. According to the Report,

“High shear strength correlated well with pressure wash results. Rigid labels tended to perform better in pressure wash than flexible labels. Greater label thickness and label rigidity reduces the tendency of the label to start peeling.

Weather – the cycling of UV-radiation, high to low temperatures, humidity and rain – is a common cause of label failure. Phase two

incorporated a 6 month (February – August) weather test in the southern California desert. Over that period researchers calculated that the labels were exposed to 4367 MJ/m2 (mega joules per meter squared) of total solar radiation, equivalent 45 cycles of MIL-STD-810G Method 505.5

procedure II accelerated testing with a weatherometer. Although this 6 month period wasn’t enough to differentiate label performance (all labels were verifiable at the end), degradation was seen in three label types: CO13 (Cable Marker Thermoplastic from CodeSource), AB12 (UV High Resist Polyester from A2B Tracking Solutions) and IK10 (TT462 Polyimide Permanent Acrylic from Identco).

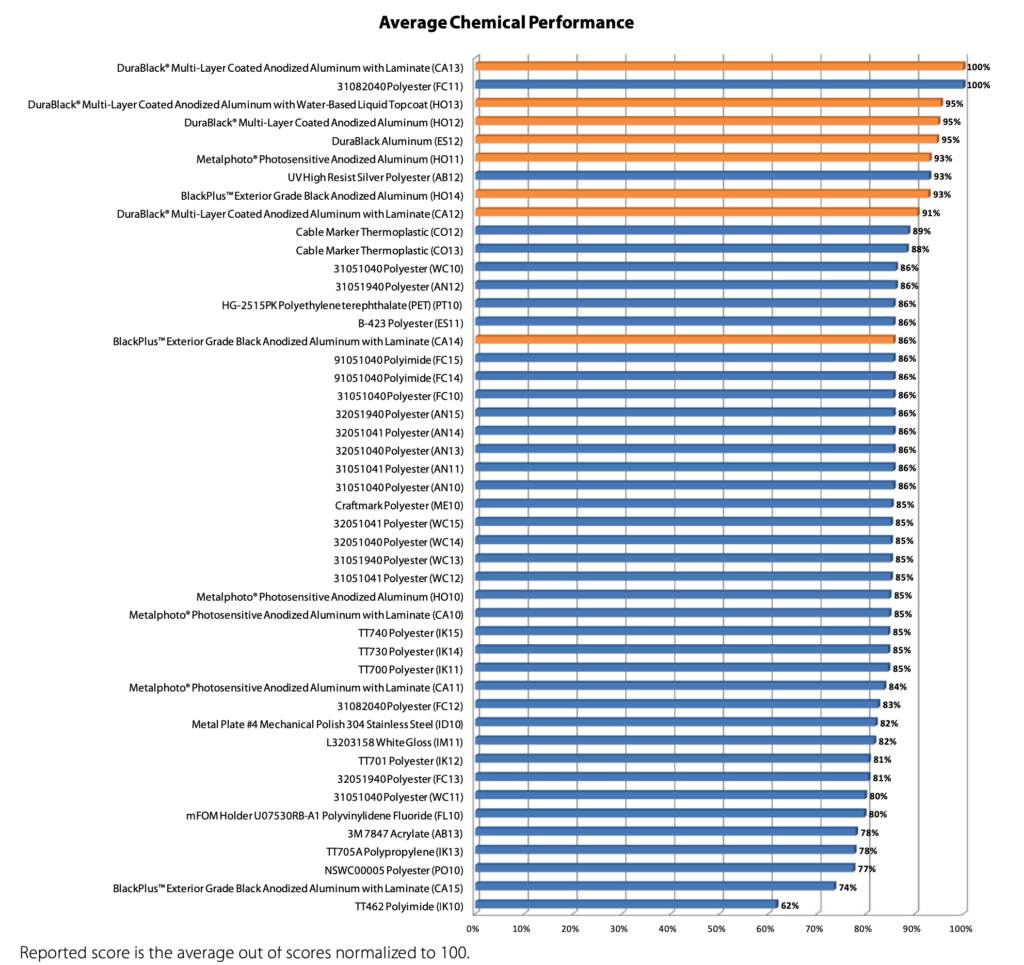

In the second phase Labels were subject to a set of 13 chemicals intended to represent the likely substances labels will come into

contact with (in phase one, Acetic Acid, Hydraulic Fluid and MIBK were tested). Labels were immersed in or coated with a chemical of interest and observed after 10 minutes and 7,200 minutes (5 days) of exposure.

Metalphoto tested in the top 90% of all labels evaluated. When protected with the SandShield overcoat, Metalphoto holds up to bleach better than Metalphoto alone; despite the durability of Metalphoto’s aluminum oxide coating, Metalphoto is susceptible to bleach. It is recommend limiting Metalphoto tags’ exposure to beach or employing SandShield, Teflon or other liquid shedding agents to minimize exposure.

DuraBlack® (another Horizons ISG product) performed the best out of any material evaluated. DuraBlack is at multi-layer coated aluminum for use with a CO2 laser. Although DuraBlack does exceptionally well on the chemical tests, it’s shortcomings on other tests, namely UV exposure and chipping, make Metalphoto a better all around label.

DuraBlack is typically used for short term(8-10 year) installation when labels must be produced on-site or in-theater. In some cases failure was attributed to adhesive detachment. As a rigid material, Metalphoto can be attached mechanically with rivets. See the Metalphoto Attachment

Guide for more information on attachment options (Figure 7).

Salt fog corrosion testing did not differentiate the materials.

Abrasion testing was conducted with two 1kg weights for up to 2,500 cycles. All Metalphoto labels scored in the top 1/7th of the labels tested with the fewest amount of error corrections required. Subsequent testing indicates Metalphoto to be extremely abrasion resistant withstanding up to 8,000 cycles on a Taber Abraser.

Although no significant differences between the labels were observed at the 160°F and -40°F temperatures tested. However, Metalphoto can withstand exposure to temperatures up to 1,000°F which is why the material is specified for labeling aluminum ingots and on-engine and aerospace tags.

Metalphoto earns the highest possible score on 32 of 33 tests for which it was given – more top scores than any other material evaluated – making it an excellent choice for a wide variety of operating environments. Further, because Metalphoto is available in thickness from 0.003” to

0.125” and can be paired with any adhesive or mechanical attachment method (unlike many plastic labels with pre-applied adhesive), it can be customized create a label system that can survive a variety of military and industrial applications.

Metalphoto’s durability comes from its photographic image which is sealed inside of the anodized aluminum, providing resistance to corrosion,

sunlight degradation, abrasion, extreme temperatures and chemical exposure. The purpose of the Navy’s tests are to identify materials that fit the needs of variety of programs, applications and combat environments. Although there is no material that dominates every test, Metalphoto photosensitive anodized aluminum did emerge as the best option for more application environments than any other material. Because real-world usage conditions are often unknown when a label is specified and applied, it is important to pick a material that will be strong in many environments. As such, the recent Corona studies confirm that Metalphoto remains one of the most durable and versatile identification materials available.

For over 50 years, industrial and military engineers have specified Metalphoto® photosensitive anodized aluminum in applications where permanent product identification is critical. Metalphoto’s durability comes from its photographic image which is sealed inside of the anodized aluminum,

providing resistance to corrosion, sunlight degradation, abrasion, extreme temperatures and chemical exposure. Available from 0.003” to 0.125” thick, Metalphoto can be used for a wide variety of applications where permanent identification is critical including barcode labels, nameplates/rating plates, maintenance schematics, machine control panels and signage.

Metalphoto can be imaged at your location where and when needed or purchased from global network of qualified processors. For more information, visit: www.metalphoto.com. Metalphoto is produced by Horizons Imaging Systems Group, an internationallyrecognized manufacturer of printable aluminum technologies. Employing a range of processes, the company’s state-of-theart manufacturing lines are located in

Cleveland, Ohio, USA.