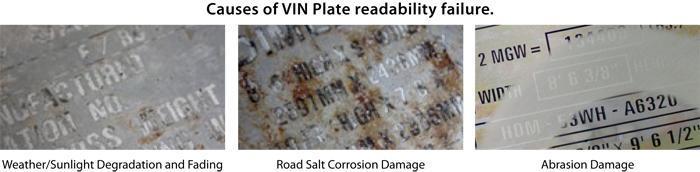

Many truck trailer and container manufacturers, historically used etched and filled stainless steel for CSC Safety Approval Plates and VIN Data Plates. However, after years of abuse from road salt, impact abrasion, and sunlight exposure, the etched plates can be difficult to read. Illegible nameplates can lead to replacement costs, inability to track trailer location and maintenance, safety hazards, and in some cases, regulatory fines.

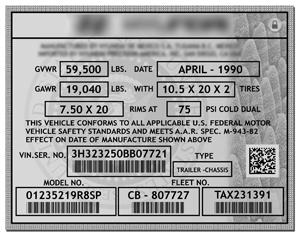

Also, because etched plates are stamped with human-readable numbers, they can lead to human error and added labor cost. After a series of failures from damaged or illegible plates, a leading transportation equipment OEM needed a VIN Data Plate solution that would both last the life of the trailer and support machine readable bar codes.

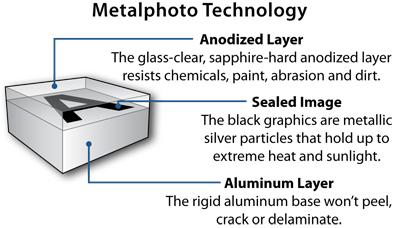

Metalphoto photosensitive anodized aluminum was identified as a solution. Metalphoto incorporates variable data barcode labels into VIN Data Plates while providing better image durability and lower cost than etched steel. Metalphoto has five key advantages over etched stainless steel:

| Metalphoto Application | Environmental Conditions | In Use Since |

| Aircraft Landing Gear Labels | Extreme temperature cyclingHydraulic & brake fluid exposureSunlight & humidity exposure | 1988 – present |

| International Space Station Labels | Extreme temperature cyclingSunlight UV radiation exposure | 2000 – present |

| Off-Shore Crane Nameplates, Labels and Operator Control Panels | Sustained sunlight/weather exposureImpact abrasionSalt-spray corrosionHydraulic fluid exposure | 1987 – present |

| Bradley Fighting Vehicle & Abrams Tank | Sustained sunlight/weather exposureSand & impact abrasionExtreme temperature cycling | 1995 – present |

| USS Ronald Reagan Nimitz-Class Nuclear-Powered Aircraft Carrier Shipboard Labels | Sustained sunlight/weather exposureSalt-spray corrosionImpact abrasion | 1998 – present |

Detailed Metalphoto performance specifications are available at www.metalphoto.com.

Trailers, chassis and converter dollies, and shipping containers are subject to prolonged exposure to extreme elements. Degradation from road salt, ocean spray, abrasion, sunlight and weather threatens the readability of CSC Safety Approval Plates and VIN Data Plates. Metalphoto photosensitive anodized aluminum is a unique imaging technology that stands up to harsh operating conditions. The UV-stable, inorganic Metalphoto image is permanently sealed inside of anodized aluminum, offering unparalleled durability and image resolution. Since 1958, Metalphoto has been specified for applications where durability is critical.

As a photographic medium, Metalphoto affords ultra-high image resolution and contrast – ideal for bar code labels. Machine readable bar code labels reduce human error and labor cost. Reducing errors and saving time is especially critical in the transportation industry where equipment must be where it needs to be, when it needs to be there and in working order. Etch and filled stainless steel is simply unable to hold consistently readable linear and data matrix bar code symbols. For this transportation OEM, Metalphoto’s ability to hold durable bar code labels was a key advantage.

In addition to the ability to incorporate long-lasting and durable bar codes, the high cost of stainless steel was of concern. Metalphoto nameplates can cost up to 30% less than etched and filled stainless steel due to material cost and processing labor costs.

Customers interested in integrating the durability of Metalphoto into their product designs can purchase finished parts from Metalphoto of Cincinnati. MPC is trusted by leaders in the transportation industry, and our experience with a variety of medium and large OEMs and shippers in the transportation space gives us the ability to properly design and manufacture a variety of identification items.

The Metalphoto Processing System is designed for reduced environmental impact. Processing solutions use low VOCs and all waste streams are neutralized or collected during the production process. Additionally, Metalphoto is designed for permanency – it will not need to be replaced. If replacement is desired, Metalphoto is easily recycled.

Leading OEMs trust Metalphoto because of its superior durability, ability to hold variable information bar codes and affordable price. However, others are beginning to take notice of Metalphoto’s versatile characteristics. Beyond durability, the Metalphoto material enables several value-added options that remove human error and protect assets from counterfeiting and destruction:

For over 50 years, industrial and military engineers have specified Metalphoto photosensitive anodized aluminum in applications where permanent product identification is critical. Metalphoto’s proprietary technology permanently seals a UV-stable image inside of anodized aluminum, offering the confidence of unparalleled durability, image resolution and readability. Metalphoto is used for component labels, machine nameplates, barcode labels, operator control panels, maintenance schematics, architectural signage and many more applications where permanent identification is critical.

Metalphoto is produced by Horizons Imaging Systems Group, an internationally recognized manufacturer of printable aluminum technologies. Employing a range of processes, the company’s state-of-the-art manufacturing lines are located in Cleveland, Ohio, USA. For more information, visit www.horizonsisg.com.