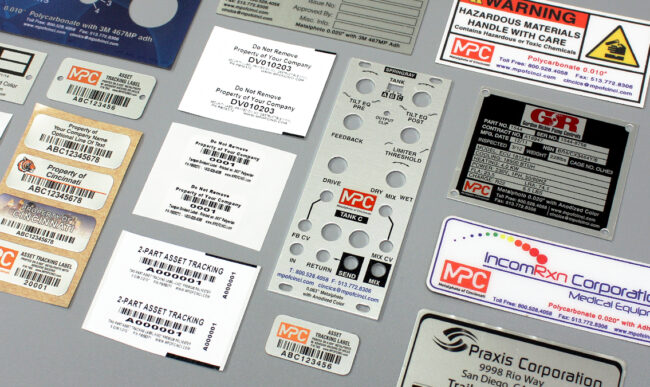

Plastic nameplates are a popular choice for tough industrial and manufacturing environments requiring a durable and cost-effective alternative to heavy metal panel nameplates. MPC’s plastic panel nameplates meet many industry standards for agriculture, construction, food service, manufacturing, marine, military, transportation, utilities/energy and more.

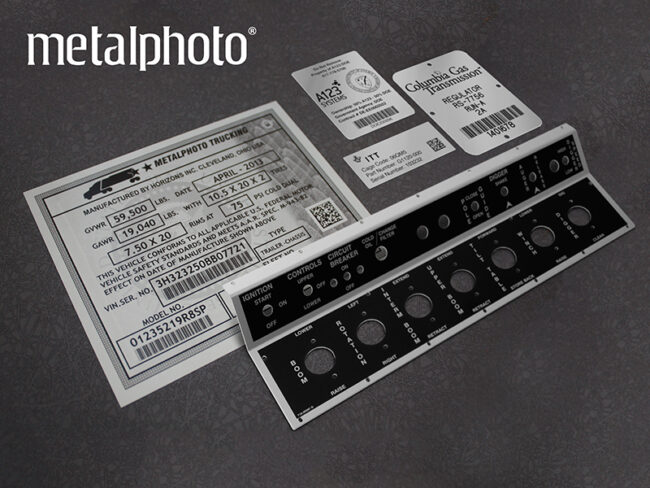

Metalphoto of Cincinnati offers nameplates in a variety of standard material options, including our proprietary Metalphoto® substrate. Metalphoto is photosensitive anodized aluminum, which features a silver and black photographic image that is embedded within the sapphire-hard anodic layer of the aluminum. This combination gives a Metalphoto part an outdoor life of over 20 years, and makes it extremely resistant to damage or degradation from environmental factors like abrasion, UV fading, harsh chemicals, extreme temperatures, and corrosion from saltwater exposure. The National Association of Graphic and Product Identification Manufacturers (GPI) Industry Standards and Practices Manual identifies Metalphoto as the most durable printed aluminum substrate available, and it has been trusted by industry, government and military organizations like Caterpillar, The US Navy, NASA, and Boeing for over 50 years. Metalphoto offers many unique features including:

Request a free Metalphoto evaluation kit today and we will send you a sample kit to test our durable identification products in your own operating environment.

Looking for other material options? MPC has the fabrication capabilities to custom build your nameplates out of many standard materials, including aluminum, anodized aluminum, stainless steel, brass, polyester, polycarbonate, and vinyl. Not sure which material is best for your application? Contact our expert sales engineers now and we’ll help you build the perfect nameplate for your project.

Our uniquely durable identification products can help solve industry specific challenges. Discover more identification and interface solutions designed for assets in your industry.

We have no minimum piece requirement. Our minimum production run is $400 per part number, excluding set-up fees/tooling. Contact us regarding your project.

Not only was their pricing competitive, but the laser engraved metal plates were done quickly and looked excellent. Their team is great with communications, and the entire experience was outstanding. They’ve definitely earned a repeat customer with us!

LeBlond Ltd. has been using Metalphoto of Cincinnati for at least 20 years with no problems. I never worry about the quality of product. We always receive competitive pricing and on-time delivery.