Rigid back panels are a great choice to reinforce and support thin metal and plastic overlays because of their structural strength. Back panels are not intended as show surfaces because they are most commonly produced using unfinished mill stock that may show surface scratches and other minor cosmetic imperfections. These imperfections are usually hidden by the overlay.

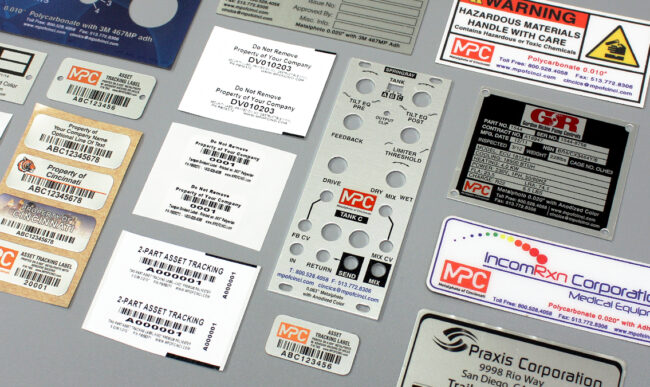

Looking for other material options? MPC has the fabrication capabilities to custom build your nameplates out of many standard materials, including aluminum, anodized aluminum, stainless steel, brass, polyester, polycarbonate, and vinyl. We also offer UltraColor, which is an anodized aluminum substrate that is sub-surface printed with a full color image, ideal for indoor environments. Not sure which material is best for your application? Contact our expert sales engineers now and we’ll help you build the perfect nameplate for your project.

We have no minimum piece requirement. Our minimum production run is $400 per part number, excluding set-up fees/tooling. Contact us regarding your project.