MPC’s brass valve tags are a popular choice for labeling pipes and valves in industrial and facility applications, where they can withstand high temperatures and other harsh environmental conditions. Brass valve tags can be polished to create a mirror-like appearance or given a slightly brushed, satin finish. A robust, malleable metal with excellent resistance to saltwater, corrosion, chemicals and solvents, tarnish, and extreme temperatures, brass valve tags are suitable for both indoor and outdoor applications. Because it won’t generate sparks, brass is also an ideal metal for use in areas where explosive elements are present.

Brass valve tags can be screen printed or chemically etched with graphics and copy, either with or without a color fill. Color graphics are not recommended for long-term outdoor applications as they have limited UV resistance, resulting in gradual degradation over long periods of exposure to sunlight.

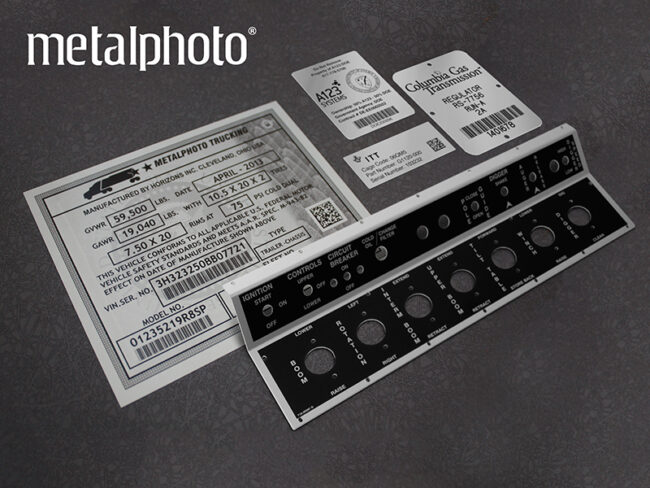

Metalphoto of Cincinnati offers nameplates in a variety of standard material options, including our proprietary Metalphoto® substrate. Metalphoto is photosensitive anodized aluminum, which features a silver and black photographic image that is embedded within the sapphire-hard anodic layer of the aluminum. This combination gives a Metalphoto part an outdoor life of over 20 years, and makes it extremely resistant to damage or degradation from environmental factors like abrasion, UV fading, harsh chemicals, extreme temperatures, and corrosion from saltwater exposure. The National Association of Graphic and Product Identification Manufacturers (GPI) Industry Standards and Practices Manual identifies Metalphoto as the most durable printed aluminum substrate available, and it has been trusted by industry, government and military organizations like Caterpillar, The US Navy, NASA, and Boeing for over 50 years. Metalphoto offers many unique features including:

Request a free Metalphoto evaluation kit today and we will send you a sample kit to test our durable identification products in your own operating environment.

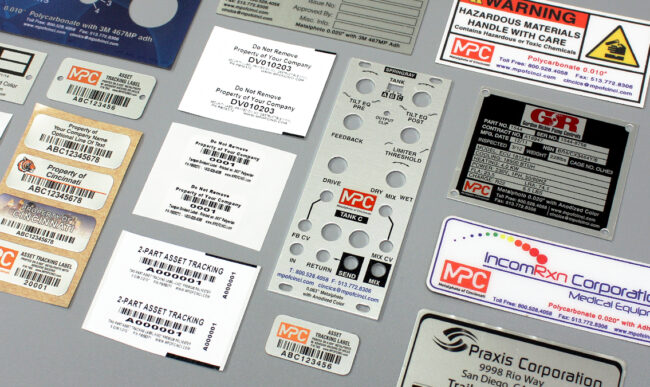

Looking for other material options? MPC has the fabrication capabilities to custom build your nameplates out of many standard materials, including aluminum, anodized aluminum, stainless steel, brass, polyester, polycarbonate, and vinyl. Not sure which material is best for your application? Contact our expert sales engineers now and we’ll help you build the perfect nameplate for your project.

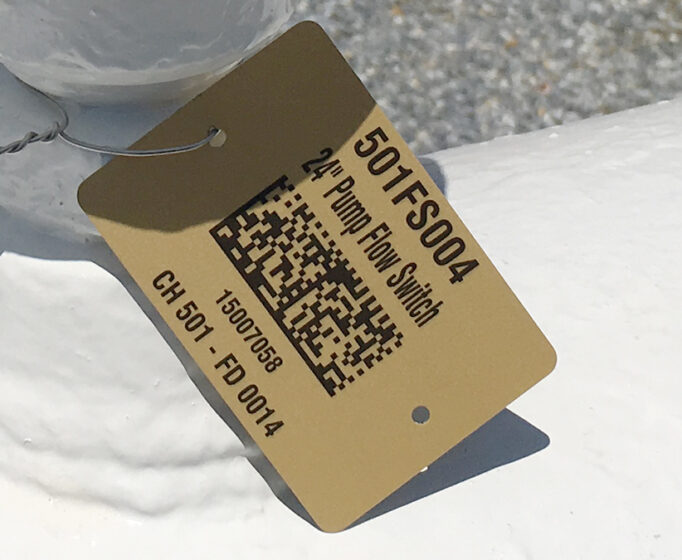

Brass valve tags are used to provide fast and reliable on-site identification of pipes and valves in facilities and industrial settings. Brass is an ideal substrate for valve tags due to its ability to withstand extreme temperatures and other harsh conditions common in these applications. Additionally, many customers appreciate the clean and professional look of brass valve tags. Here are a few of the benefits of brass valve tags:

Brass valve tags are suitable for use in both indoor and outdoor applications thanks to their resistance to saltwater, corrosion, and tarnish. For applications requiring maximum strength, Metalphoto® valve tags may be a more suitable option.

In facilities and industrial applications, valve tags are exposed to a variety of harsh environmental conditions such as chemicals and solvents and extreme hot and cold temperatures. Brass is capable of withstanding these conditions, remaining readable over time.

We have no minimum piece requirement. Our minimum production run is $400 per part number, excluding set-up fees/tooling. Contact us regarding your project.

Brass valve tags are versatile and can be found in many facilities, as well as commercial and industrial applications. Brass is often selected as a valve tag substrate when customers want valve tags to be noticeable and strong enough to last for many years. The unique characteristics of brass valve tags make them suitable for the following applications.

Our uniquely durable identification products can help solve industry specific challenges. Discover more identification and interface solutions designed for assets in your industry.