What Is OEM? Definition, Relationship with VARs, Benefits & More

Spend any amount of time in manufacturing, and you’re certain to hear the term ‘OEM’ thrown around. In simple terms, OEM – shorthand for original equipment manufacturer – traditionally refers to businesses that build and produce specific parts for other companies. These companies then go on to use these components in the manufacture of their final product.

Though OEM parts themselves rarely take center stage in the eyes of the end consumers, they play an outsized role when it comes to quality, cost-effective manufacturing. Unless a company has the resources to ground-up engineer every component necessary for full functionality of their end product, OEMs are critical business partners with manufacturers of consumer-facing goods. To illustrate the importance of OEMs in more detail, we’re exploring how they fit into the traditional manufacturing business model and the value they add to the engineering process.

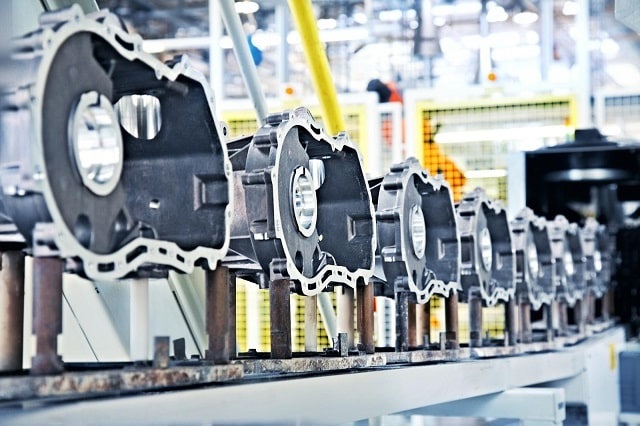

When it comes to manufacturing, many larger, more complex products that you see for sale as a consumer aren’t entirely engineered in-house by the seller. Perhaps the best example of this is the automotive industry. The average car incorporates thousands of parts, from valves to springs to switchgear to sound deadening. Does GM or Toyota task their army of engineers to design every window switch, engine gasket, or electronic sensor that their products require? No – they farm out the work to proven suppliers that have made it their job to design and build quality components at scale.

These suppliers are known as Original Equipment Manufacturers because they engineer and manufacture original componentry that they’ve contracted to sell to the automakers. The automakers, meanwhile, are known as the Value-Added Resellers, or VARs. They’re known as such because they take these individual components and package them into a more valuable final product that is desired by the end user. Nobody is looking to buy a cruise control stalk by itself – they want it attached to a fully-functional new car.

This is the case not just in the automotive industry but in all complex manufacturing of goods. Computer manufacturers like Lenovo and Dell buy internal components like circuit boards and chips from OEMs. The aerospace industry uses OEMs to build certain ancillary aviation componentry. Even medical equipment manufacturers work with OEMs to develop certain parts.

Essentially, the OEM and VAR relationship is that of a contracted purchase agreement. The best way to understand it is through an example.

Let’s say company A is the VAR – the company that buys parts to manufacture their own product. During the engineering process, they determine that Widget Z is something they don’t want to design and build in-house due to cost, complexity, capacity, or some other practical limitation. They then reach out to Company B, an OEM specializing in building parts like Widget Z.

After some talks, the two businesses agree that Company B will supply Company A with Widget Z at an agreed-upon price point and quantity. Once production begins, Company B will send batches of Widget Z to Company A, which will use them to manufacture its own product.

The end consumer may never see or even think about Widget Z. That’s the case with many OEM components – though they often serve a critical role to product functionality or user experience, these components are so unassuming or seamlessly integrated into the final design that most buyers won’t know they were engineered by a secondary company.

There are plenty of great reasons for manufacturers to work with OEMs, but we consider the following benefits some of the most significant:

An OEM is often a niche expert who knows exactly how to build a specific component at scale. They’ve already done the foundational engineering and understand the complexities and challenges of their particular specialty. This baseline knowledge allows them to hone in on exactly what you need and deliver a product that meets your expectations.

As established specialists in their product of choice, an OEM likely doesn’t need the longer lead times an inexperienced in-house engineering team might require to develop a comparable part or product. They have the right knowledge, production capacity, and expertise to move quickly and supply you with the parts you need when you need them.

Perhaps the most significant benefit is the potential for reduced cost. To replicate the quality and precision of specialized OEM parts, a VAR would have to earmark precious time and resources for their own team to design, prototype, finalize, and produce the parts they need. MEANWHILE, an OEM that already builds comparable componentry can quickly adapt its own manufacturing processes to accommodate your parts – likely saving you precious R&D money in the long run and freeing up your staff to shift their focus elsewhere.

OEMs have often been in the game a long time, which means they know how to do what they do quite well. They can reliably create durable, trustworthy parts at scale that you can feel confident using in the assembly of your final product.

It’s easy to confuse OEM with aftermarket, as both seem to refer to companies that build parts for the VAR. The difference is simple yet significant: the OEM builds parts designed to be used in the original manufacture of a product. Aftermarket companies design solutions after the fact to create alternative replacement parts, often at a lower price than OEM componentry.

The difference is important because only OEM parts were originally engineered for the product they were used in. They were developed by trusted suppliers to the VAR and fit with a certain exactness and precision that aftermarket companies may or may not be able to match. It’s why many people prefer buying OEM parts when servicing equipment, whether they’re buying an oil filter for their personal vehicle or aircraft parts for their company’s fleet of Boeing 747s.

Meanwhile, the benefit of aftermarket components is that they often offer a more affordable alternative to a replacement OEM part. Think of them like the generic drugs you can buy in lieu of the name-brand option and you have the right idea. You can likely save money without sacrificing on quality with many aftermarket parts, but OEM will always remain king when it comes down to exact fitment as well as perceived quality and durability.

VARs and other companies that need to maintain equipment and replace parts must be able to identify the authenticity of OEM parts. Identification tags such as metal nameplates and equipment ID tags can provide conclusive product identification as well as essential information such as service information and warranty information.

The challenge lies in ensuring that an OEM part is identifiable throughout the part’s lifespan, particularly for parts that are exposed to harsh environmental conditions such as manufacturing, industrial and outdoor applications. Exposure to chemicals, solvents, UV, extreme temperatures, abrasion, and other conditions in the application’s operating environment can degrade ordinary tags and labels and reduce readability over time.

That’s why Metalphoto® photosensitive anodized aluminum is the material of choice for OEMs across every industry. With the image sealed beneath an anodic layer of aluminum, Metalphoto tags offer superior durability in a variety of operating environments, including extreme environmental conditions and even in outdoor applications. In fact, Metalphoto is recognized by the National Association of Graphic and Product Identification Manufacturers (GPI) Industry Standards and Practices Manual as the most durable printed aluminum substrate available. With an expected lifespan of 20+ years in outdoor environments. OEMs that tag parts and equipment with Metalphoto tags give their customers the assurance of authenticity as well as ensure that essential service and warranty information is readily accessible throughout the lifespan of the asset.

Original Equipment Manufacturers do many things for both their business clientele as well as consumers. With their engineering expertise, OEMs can help speed up product development programs, quickly and cost-effectively scale the manufacture of specialized or specific parts, and product quality, long-lasting parts that consumers have come to trust.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›