What are the Sanitary Welding Standards for Food-Grade Applications?

If your facility centers around food processing, then you know that following the latest sanitary and hygienic design standards isn’t something to be taken lightly. Flocks of agencies have put stringent standards into place to ensure that the food-grade goods that you are manufacturing are consistently safe. But when it comes to food equipment hygienic design, specifically, the program that must be strictly followed is the FDA’s FSMA or Food Safety Modernization Act.

Among other things, the FSMA focuses in on the potential weak spots that could be hiding in your equipment, such as insufficient surface roughness, clogged drainage ports, and faulty design elements like angled exteriors. Breaking FSMA down into layman’s terms: no food should ever come into contact with porous surfaces, and all equipment must be able to be taken apart easily for frequent cleanings.

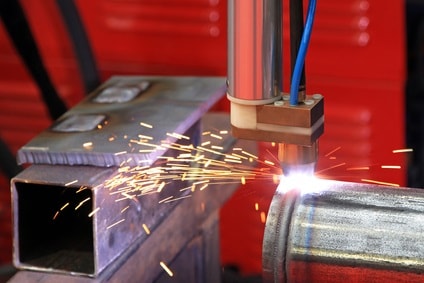

As you’ve likely surmised, one of the most notable challenges that come with following FSMA for food-grade applications is the fact that all welded surfaces must be free of any cracks and crevices. That’s because food remnants can easily get lodged in these tiny cracks, resulting in possible contamination, not to mention general uncleanliness. Strict welding standards and practices must be put into place to ensure that your facility, as well as the rest of your supply chain, are adhering to the regulations.

Let’s take a look at the some of the key elements that make up the welding standards:

Because all surface finishes must be smooth, framework, such as tubular piping, should be sealed together in such a way that allows for easy disassembly for cleaning or automatic self-draining. When working with these designs, you should avoid penetrating the materials with bolts, rivets, or studs. Any crevices that form from faulty welding practices should be smoothed so that the roughness average (Ra) does not exceed 0.8µm. When necessary, screw threads can be used, but they must be sealed.

Additionally, all equipment must be sealed following the above guidelines during the installation process, with the maximum amount of space possible. Leaving at least four inches of space between the equipment and the wall makes it possible for workers to identify potential hazards, such as leaks and rodent activity, as they occur.

When reading the FSMA, one point that is mentioned repeatedly is that corners, angles, and porous surfaces are veritable breeding grounds for bacteria. When food gets trapped in these crevices, dangerous cross-contamination could occur.

To discourage this from happening, the FDA wants all producers to use only designs with internal angles and corners so that they appear softer and radiused. This means that welds should never be made in the corners, but only along completely flat surfaces.

Welders might be able to get away with leaving microscopic burrs on surfaces in some applications, but it must be avoided when working in food-grade environments. Because keeping the Ra down as much as possible is the name of the game, performing extremely meticulous work is extremely important.

If burrs or sharps are compromising your surface’s Ra, certain welding processes can be used to minimize the mistakes. This can be done through sanding, electropolishing, or other specialized smoothing techniques.

When working with stainless steel, specifically, welders must avoid using techniques that could cause too much stress on the surface. An overstressed surface can mean many things, but when looking at food-grade welding mistakes, it usually means that the protective oxide layer is in danger of being stripped away.

This can be a particularly devastating blow to the surface’s Ra because, without the oxide layer, the stainless steel is now susceptible to corrosion.

Of course, welders must also stay away from using any techniques that might introduce stress cracks or microfractures in the equipment’s surface. According to Marlin Steel, processes like resistance welding match well with the needs of food-grade stainless steel, as long as they’re performed well. Remember, when the surface is subjected to too much force or heat during the weld, stress cracks that lead to corrosion could occur.

Avoid welding together dissimilar metals at all costs. Here are some of the risks that can occur when welding dissimilar metals:

Typically, this mistake is made by inexperienced engineers during the design phase. To avoid this potential pitfall, make sure that your in-house engineers or safety teams are educated on the ins and outs of your equipment supplier’s design. This will not only help you get a better idea of their understanding of hygienic design as a whole, but it will also guarantee that more of your bases are covered when inspection time rolls around.

When it comes to food-grade applications, there are regulations that impact every facet of the design, manufacture, and use of equipment. Welders working with food-grade applications must be well-versed in these standards to ensure the integrity and safety of the equipment.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›