Industrial equipment labels are used by companies throughout the world as a convenient way to mark their important assets. Given the high capital cost and demanding upkeep that most of these assets require, it’s important to properly manage all of the critical details for each item. Many businesses use industrial equipment labels to share important information including barcodes and also demonstrate clear ownership.

When choosing an equipment label you should always carefully consider your requirements, application, and label design. In this post, we’ll take a look at the best way to prepare for your order and make the most out of your label selection. Industrial equipment labels are a versatile and durable asset management solution, with options that can meet even the most unique requirements.

One of the most critical decisions to make when choosing an industrial equipment label is selecting the right substrate material. To ensure maximum compatibility with your intended applications, consider any potential environments where your industrial equipment may be stored. These can include warehouses, outdoor locations, trucks, buildings, and factories. For each location, identify any potential hazards that may be present such as moisture, chemicals, and sources of abrasion. Since it is not possible to prepare for every scenario, this process can really help you understand the level of label durability your application requires.

Once you understand the sources of potential damage, you can then select a substrate material that is most compatible with those parameters. Industrial equipment labels can be fabricated with metals, plastics, or polyester, giving you a wide range of choices to fit your specific needs. Additional requirements to consider are label positioning, barcode scanning, and the attachment method. All of these considerations combined will help you narrow down your potential selection to a few label options.

Once you understand the type of label material and basic design requirements for your application, it is much easier to select from a specific style of industrial equipment label. There are many options available to suit unique application specifications. Some labels can be used in many different situations, while others are intended for a very specific use case. Here’s a look at common use cases and the types of industrial labels and tags that are suitable for each.

After identifying your label specifications and determining your application, you can confirm a few final details and have your labels created, shipped, and delivered. Before placing an order, it’s always a good idea to review your final design and confirm the expected label order quantity. You may also have a need for label blanks, which can be purchased for onsite engraving, embossing, or stamping. This is often desired for businesses that frequently relabel equipment or are managing work-in-progress (WIP) processes.

By working with a trusted partner, you have access to experts who can review your specifications and make recommendations if there are any questions about compatibility or design fit. The selection process is as easy as following a few simple steps to choose a design that is optimized for your industrial equipment labeling needs.

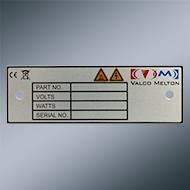

Industrial equipment labels need to convey key information such as the manufacturer’s name, model number, serial number, and any relevant regulatory approvals or certifications. This information is important for traceability, maintenance, and compliance purposes.

When selecting labels for industrial equipment, it’s crucial to consider the environmental conditions the labels will be exposed to, such as moisture, chemicals, abrasion, and temperature extremes. The label substrate, adhesive, and topcoat need to be durable enough to withstand these conditions over the lifespan of the equipment.

The most common types of industrial equipment labels include compliance tags, data plates, nameplates, safety labels, and instructional labels. The specific labels needed will depend on the equipment, its application, and relevant regulations or standards.

To ensure the labels are sourced and applied properly, it’s recommended to work with an experienced label converter, test label performance under real-world conditions, and maintain traceability records. Proper label application is also crucial for long-term durability and legibility.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›