Nadcap (formerly known as the National Aerospace and Defense Contractors Accreditation Program) is a worldwide cooperative program of major companies designed to manage a cost-effective consensus approach to special processes and products and provide continual improvement within the aerospace and defense industries.

We’ve created this guide to provide everything you need to know about Nadcap auditing, accreditation, requirements, and accreditation. To jump to a specific section, use the links below:

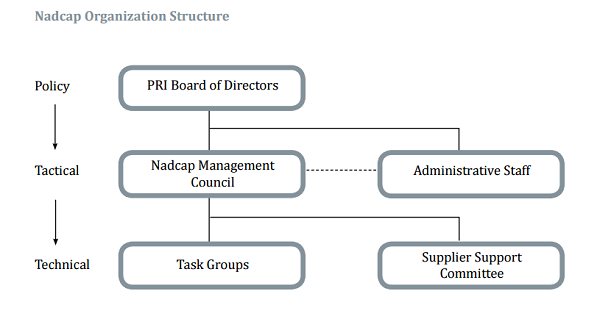

Nadcap is “an industry-managed approach to conformity assessment” bringing together technical experts from both government and industry with the goal of establishing accreditation requirements, issuing accreditation to suppliers, and defining operational program requirements.

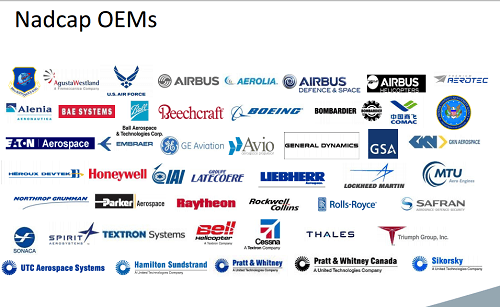

Before Nadcap, aerospace companies audited their own suppliers to verify compliance with their own process requirements. The result was duplicate audits that proved redundant and essentially created a larger workload without adding value. But aerospace prime contractors, including original equipment manufacturers (OEMs) can often trace the root cause of failed components to a flawed special process on the supplier end, so audits are both necessary and desirable for mitigating failure risks associated with flawed supplier processes. The Performance Review Institute (PRI) was incorporated in July 1990 to administer the Nadcap program in order to eliminate duplicate supplier process control system audits for a variety of special processes utilized in the aerospace industry.

Screenshot via PRI

Overall, Nadcap enables suppliers to gain tighter controls over special processes and also provides a forum for industry members to have a voice in the establishment of audit requirements. Additionally, Nadcap offers opportunities for networking and market recognition. Other Nadcap functions include:

These efforts result in more frequent audits for Primes and fewer audits for Suppliers.

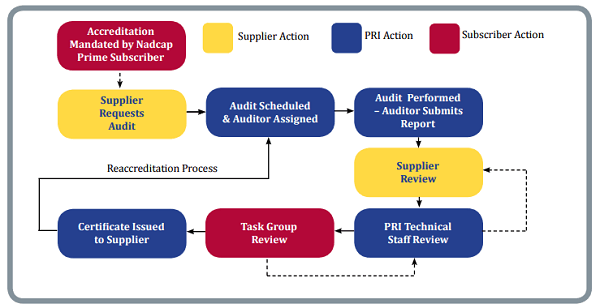

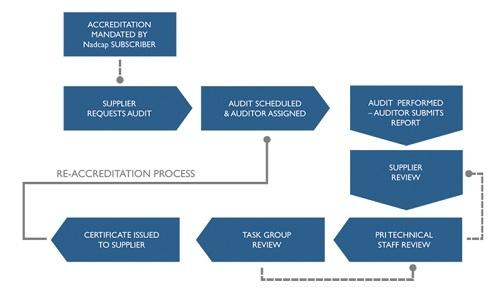

Nadcap audits against the industry-agreed Audit Criteria (AC). The auditing process is tied to the accreditation process, and it’s necessary for suppliers to have a completed audit (with any non-conformity issues resolved) before accreditation is issued.

At the supplier request, the PRI schedules audits and assigns industry-approved auditors to carry out the audits against established, agreed-upon industry standard checklists. If non-conformance issues are discovered in the process, a non-conformance report is issued, and PRI then administers the closeout of these reports.

Screenshot via PRI

On completion, the completed audit package is presented to a special process task group, comprised of members from the industry, which will then review and vote on its acceptability for approval. When all non-conformances are closed, accreditation is granted.

The overall Nadcap process can be outlined in several key steps:

To prepare for a Nadcap audit, you should first locate the relevant documents and specifications. A good starting point is eAuditNet, which is developed and maintained by PRI. In addition to valuable materials you can reference throughout an audit, you’ll also find procedure outlines on both pre- and post-audit processes, including response time frames, tips for reducing the frequency of audits, and what to do if non-conformance issues are discovered during an audit. When you’ve fully prepared, you can also schedule an audit directly through the eAuditNet website.

Auditable activities comprise 17 main groups, known as “Special Processes,” with each led by a Task Group and including multiple sub-programs that can be included in the scope of an audit. Task Groups consist of Prime Contractors, Government Representatives, and Suppliers who work together to generate a consensus on creating or revising the Audit Criteria (checklist). Task Groups are responsible for:

As above, prime subscribing members of each Task Group also have some additional responsibilities including:

Additionally, Task Groups may utilize ad-hoc sub-teams as needed at any time based on industry needs.

Below, the 17 Special Processes are listed along with the industry standards each task group is focused on, or the standards to which the task groups conduct audits to demonstrate compliance:

On eAuditNet, you’ll find the applicable audit checklists that you’ll need to adhere to. In many cases, there are multiple checklists that apply to specific accreditation areas. For instance, if you’re seeking accreditation in the Heat Treating category, there are several checklists that apply to all sub-programs in this category, and depending on your specific processes, additional checklists may apply. The checklists applicable to all sub-programs in the Heat Treating category include AC7102 Revision H – Nadcap Audit Criteria for Heat Treating; AC7102/8 – Nadcap Audit Criteria for Heat Treating Pyrometry; and AC7102/S Revision F – Nadcap Supplemental Audit Criteria for Heat Treating.

Screenshot via PRI

If you already have an acceptable quality system approval, be prepared to provide this information when you request an audit. If you don’t already have an acceptable approval, AC7004 (Aerospace Quality Systems) or AC7006 (for laboratories) will be added to the standard accreditation process. AS9100 is also considered acceptable, and it’s based on the ISO 9001 quality system requirements, although ISO 9000 is no longer deemed an acceptable pre-requisite. AS9120 is another important standard that relates to quality management systems. It’s based on AS9100 but adds specific requirements relevant to stockist or pass-through distributors for the aerospace industry. The AS9110 standard relates to maintenance organizations. Also based on AS9100, AS9110 adds specific requirements that are critical for the maintenance of commercial, private, and military aircrafts.

Additionally, you’ll need to allow time to prepare and conduct an internal audit prior to your Nadcap audit; it’s a required component of the overall auditing process. Essentially, an internal audit is an unbiased assessment of your strengths and weaknesses compared to the applicable Nadcap Audit Checklists. Your internal audit must be completed and submitted to Nadcap at least 30 days prior to your scheduled formal audit. Of course, it’s a good idea to conduct your internal audit several months in advance, which allows time to make changes to better comply with the requirements.

The auditing and accreditation process is complex and stringent, so it’s beneficial to enlist the aid of a third-party consultant who can help your organization prepare and get through your Nadcap audit successfully. Expert Resource, for instance, has experts in every Nadcap area, including less-common areas such as Sealants, Electronics, Composites, and Measurement & Inspection, and 100% of Expert Resource clients pass on their first attempt. Companies who make their first attempt on their own often turn to Expert Resource for help implementing corrective actions, as well, and they’ve helped clients win appeals 100% of the time. Finally, Expert Resource can also help companies obtain state or federal funding to help offset the costs of audits and accreditation.

Even if you choose to enlist the aid of a consultant, you should be familiar with the steps involved in Nadcap accreditation. An internal audit is the first phase in the process. There are several steps involved in performing an internal audit, including:

Utilize the Nadcap checklists when conducting an internal audit to simulate the formal auditing process as closely as possible and pinpoint potential issues. You can also enlist an external consultant to conduct an internal audit, which can result in a less-biased process with more accurate findings.

As you work through the audit, document all areas of compliance – complete with objective evidence if possible – as well as weak areas to improve upon before your official Nadcap audit. Note that job audits include tracing of a job from contract review through shipping. This enables Nadcap to determine if customer requirements are met through the flowdown of the process. If you have questions regarding audit criteria, you may contact staff engineers at PRI.

Official Nadcap audits generally take two to five days and attempt to minimize disruption to normal supplier operations. The length of time an audit will take varies based on the scope of the audit, or the number of checklists and processes included, and the cost of an audit varies based on length. Most suppliers opt to have only one special process audited at a time. The estimates below are approximations per special process audit in North America and include travel costs for auditors:

Audits follow the general auditing protocol, which includes an introductory or in-briefing meeting as well as an exit or out-briefing meeting upon completion, although non-conformances are identified on a daily basis throughout the audit.

For non-conformances, Nadcap requires a five-part corrective action to include:

Task Groups may require follow-up audits in the event of non-conformances in order to:

After corrective action has been implemented for all non-conformances (to the satisfaction of the relevant PRI staff engineer), the complete audit report is submitted to the subscribing Primes of the applicable special process task group, who are considered experts in the special process being audited, to verify the staff engineer’s conclusion and approve the audit for accreditation.

Nadcap accreditation requirements are determined by each respective Task Group and relate specifically to the Special Process in question as well as its sub-programs. In addition to the specific Special Process requirements, suppliers are required to have a quality system certification to AS9100 (or an acceptable equivalent) from an approved, third-party accreditation body prior to being eligible for Nadcap accreditation. However, suppliers who do not have an acceptable equivalent quality system certification prior to scheduling an audit can add an additional audit day for the PRI AC 7004 quality system audit, or AC7006 for laboratories. In many cases, adding the AC 7004 / AC 7006 quality system audit to your Nadcap special process audit is a more cost-effective option.

In addition to all specific audit requirements related to special processes, Nadcap and PRI are committed to compliance with all government export control regulations, including the International Traffic in Arms Regulations (ITAR) and the Export Administration Regulations (EAR), which affect the manufacturing, sale, and distribution of technology.

There are several important resources to help you understand and comply with these requirements:

Nadcap expects all participants to ensure the appropriate handling of all export-controlled materials within their facilities at all times, and as such has built several safeguards into the audit process. Some auditors have restricted EC status, which means they’re unable to perform audits for ITAR/EAR-restricted work. For this reason (and to avoid unnecessary rescheduling and fees), it’s important to disclose whether work is done under ITAR/EAR guidelines at the audit scheduling stage. You should also ensure that any PRI email recipients have an unrestricted access before sending any electronic communication including Export Restricted data or technology.

Nadcap accreditation is associated with excellence in the aerospace industry. Accreditation is awarded at the company level for specific processes (outlined in the Nadcap Auditing section) used by aerospace suppliers, such as chemical processes and coatings. The accreditation program is highly regarded because it’s led by the industry and utilizes qualified, experienced industry professionals to conduct process audits, which are based on agreed-upon criteria specific to the process being evaluated.

Some suppliers pursue Nadcap accreditation because their customers are asking for it, and in other cases, it’s mandatory for conducting business with companies such as Airbus, Rolls Royce, Boeing, and Honeywell. In any case, Nadcap accreditation is a vote of confidence – industry-consensus verified – that your operation follows industry-recognized best practices. Compared to general quality systems standards, such as ISO 9000, Nadcap digs deeper to ensure the quality of highly specific processes based on proven methodologies.

Screenshot via NIST.gov

According to Nadcap’s 2009 Supplier Survey, 83 percent of suppliers reported quality improvement in their areas of Nadcap accreditation. Additionally, a web poll in June 2010 (one month prior to Nadcap’s 20th anniversary) resulted in the following findings:

Suppliers aren’t the only entities that benefit from Nadcap’s comprehensive, industry-managed special process accreditation process; prime contractors reap many benefits, as well, including:

The initial Nadcap accreditation is typically based on a 12-month cycle, with reaccreditation audits (which follow the same process as the initial audit) being scheduled automatically. However, note that the actual length of the subsequent accreditations may vary based on audit performance.

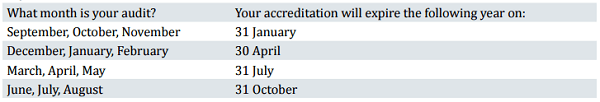

Reaccreditation audits are scheduled based on the date of the initial audit, rather than the date of accreditation (e.g., two suppliers audited in September 2017 will be scheduled for a reaccreditation audit in January 2018, even if one supplier gains accreditation in November 2017 and the other not until February 2018). A delay of several months for corrective actions will ultimately lead to a shorter accreditation period, so preparing well for audits in order to pass the first time is well worth it and will extend the time between audits.

The following chart illustrates the typical accreditation period:

Screenshot via PRI

Nadcap also has a Supplier Merit Rewards program, which awards reduced scope or extended-frequency audits to suppliers who demonstrate exemplary audit performance. This is determined by the Special Process Task Group. Initial audits have an accreditation period of 12 months from the first quarter in which it’s eligible for review, while the following two reaccreditation audits have accreditation periods of 12 months from their prior expiration. Subsequent reaccreditation audits are awarded for periods of 12, 18, or 24 months based on the supplier’s performance.

While special process accreditation is at the core of Nadcap, PRI manages a number of valuable programs and offers opportunities such as professional development, meetings held several times each year, and a supplier support committee. There are also opportunities for suppliers to get involved at the Task Group level in Nadcap, with the exception of matters related to accreditation.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›