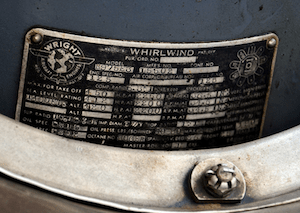

Aircraft data plates contain all of the vital information about an aircraft. Typically made of metal, aircraft data plates are etched with registration information such as date of manufacture, model number, serial number, and registration number. The Federal Aviation Administration (FAA) requires that all aircraft have a data plate, even those that are built by amateurs.

Regulatory requirements for aircraft data plates are found in 14 CFR Part 45, Identification and Registration Marking, which is specified in 45.13 Identification Data: the identification must include the builder’s name, model designation, builder’s serial number, type certificate, if any, and production certificate number, if any.

Furthermore, the FAA states where these plates must be placed in Part 45.11: “[T]he aircraft identification plate must be secured to the aircraft fuselage exterior so that it is legible to a person on the ground, and must be either adjacent to and aft of the rearmost entrance door or on the fuselage surface near the tail surfaces.” Thus, the regulation specifically requires them to be placed on the exterior of the aircraft; it may not be mounted on an interior surface, regardless of whether it is visible from the outside.

Furthermore, the FAA states where these plates must be placed in Part 45.11: “[T]he aircraft identification plate must be secured to the aircraft fuselage exterior so that it is legible to a person on the ground, and must be either adjacent to and aft of the rearmost entrance door or on the fuselage surface near the tail surfaces.” Thus, the regulation specifically requires them to be placed on the exterior of the aircraft; it may not be mounted on an interior surface, regardless of whether it is visible from the outside.

Overall, the FAA regulations state that ID plates must be mounted to the exterior of an aircraft and should not be attached in a way that will likely result in it being defaced or removed during normal service. It’s also important to note that they must be attached in a manner that will prevent them from being lost or destroyed in an accident. Therefore, data plates should not be placed on an inspection cover or access door or any other part of the aircraft that is removed for maintenance purposes or inspections. That’s why the FAA stipulates that plates must be attached to the fuselage.

Aircraft often are subjected to extreme temperatures, sunlight exposure, abrasion, and corrosion, which can affect the readability of data plates. There are some materials that stand up better to these harsh conditions than others, such as Metalphoto photosensitive anodized aluminum. Data plates constructed of this material are extremely durable and lightweight and offer outstanding resistance to abrasion, extreme temperatures, sunlight, corrosion, and chemicals. Metalphoto has been proven to remain durable for more than 20 years because its image is sealed beneath a sapphire-hard anodic layer. As such, Metalphoto data plates have been qualified by aerospace and government organizations including Boeing, Lockheed Martin, BF Goodrich, NASA, and Honeywell, Inc.

For any number of reasons, an aircraft owner may not have an original identification plate issued by the aircraft manufacturer. Should a data plate become lost, stolen, or damaged during maintenance, a FAA Legal Interpretation issued by their Office of the Chief Counsel states that the owner should “seek a replacement from the aircraft’s original manufacturer.” In some cases, manufacturers may hesitate to issue new data plates because of product liability exposure, or the manufacturer may be out of business. In that case, the FAA Interpretation states that owners or operators may buy data plates from an approved source after contacting the local Flight Safety Standards District Office or Manufacturing Inspection District Office for assistance and approval in getting a replacement.

The FAA Interpretation also warns aircraft owners against purchasing a reproduction data plate sold online because it may not be produced by the manufacturer or an FAA-approved alternative source and cannot indicate to the FAA that the aircraft conforms to its type design. When the aircraft is missing an approved data plate, it cannot prove conformity and the aircraft is deemed ineligible for a standard airworthiness certificate.

Overall, it is best to avoid purchasing replacement data plates from some sources on the internet because you may be left with a reproduction plate that is not up to par with the FAA standards and regulations. It is better to obtain a replacement data plate from the manufacturer when possible or from an approved source to ensure compliance.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›