ABYC Standards: What Boat Builders Need to Know to Stay Compliant

When it comes to developing, implementing, and policing initiatives concerning workplace safety, sanitation, public health and more, the United States leads the way. As it happens, the U.S. also boasts a comprehensive boat safety sector, one that is comprised of several organizations that contract with public and private entities to ensure the best possible structural outcomes for marine professionals, passengers, and our fragile environment. One such organization is the American Boat & Yacht Council (ABYC), a non-profit group that consists of hundreds of marine industry professionals who volunteer their time to establish the most influential boat safety strategies in the world.

Nevertheless, just because ABYC writes the rules doesn’t mean that the path to compliance for boat makers is always an obvious one. You see, the Council’s regulations are designed to be self-governed by the manufacturer, a fact that makes for a simpler build process, but also one that can make responsible boat makers second guess their final products. Luckily, the ABYC makes things like self-compliance and individual certification simple paths to follow. After reading this how-to, you should be ready to dive into ABYC compliance on your own.

In today’s guide, we’ll discuss:

The American Boat & Yacht Council, widely referred to as ABYC, is a non-profit organization that provides its members with information on safe boat construction and repair. Additionally, ABYC invests much of its time and resources into developing global safety standards for vessel design and construction.

Soon after being established in 1954, ABYC became a member of the American National Standards Institute (ANSI), an organization that oversees the development of standards across a variety of different industries. As you’d expect from the Council’s background, ABYC focuses much of its energy into researching the standards that it develops, but it also provides plenty in the way of education and professional support. The organization routinely holds seminars, workshops, and technical certification courses that are aimed to provide members with the tools needed for simple compliance adoption.

According to the Council, the education and standards teams are represented by a voluntary group of experts who are committed to design safety and efficacy, including “boat builders, technicians, engineers, boat and accessory manufacturers, surveyors and investigators, retailers and dealers, yacht brokers and designers, marinas, law firms, government agencies, boat owners, insurance companies and more.”

ABYC’s current collection of standards, entitled, Standards and Technical Information Reports for Small Craft, is a newly-updated compliance guide for boat makers and covers all of the major boating systems.

The backbone of the ABYC is not just its large directory of members or even its partnership with ANSI; it is actually the 400 voluntary marine professionals that are the ones who develop the iron-clad safety standards through collaboration. The 16 Project Technical Committees (PTCs) bring to the table their decades of experience and, after the standards are empirically tested and written, share them with safety organizations the world over. ABYC’s process is worth outlining for a number of reasons, one of them being that the Council uses only peer-developed standards that the individuals writing them will be made to follow. Boat builders can rest assured knowing that their acts of compliance are ones that are drafted and upheld by industry leaders and industry leaders only.

It’s important to note that neither ABYC nor any other body actually certifies vessels (although there are other certification programs, such as Yacht Certification, which are based on ABYC standards), making it the responsibility of the manufacturer to ensure full compliance. That said, over 90% of boats on the water adhere to ABYC standards, which illustrates how highly today’s boat makers regard public safety. Manufacturers who are found to be in full compliance enjoy increased liability protection, as well as automatic compliance internationally (in most cases).

With that said, let’s take a look at some of the ABYC standards basics. At present, the ABYC standards cover 80 key application points directly related to small craft. They are as follows:

As you can see, the standards are comprehensive and cover everything from the vessel itself to components such as marine generators, marine propellers, and more.

Non-members are able to access short explanations for each document on the ABYC website, but boat builders seeking certification will need to either become members of the Council or purchase its 2018-2019 (or most current) manual to access full descriptions.

Because the ABYC doesn’t provide its own way to ensure compliance, it focuses much of its efforts on education through its signature certification programs. This is an important detail for boat builders to consider as they welcome new engineers and technicians onto their teams. At this stage, the Council provides eight standards certification courses modeled from its own regulations. They are as follows:

Each of the eight courses is developed specifically for marine professionals. In 2019, roughly 3,500+ technicians and engineers had become certified through ABYC’s nationally-accredited program, which is verified through third-party, NOCTI Business Solutions. Applicants have the option to obtain certification by going through one of two routes: in-person certification courses or self-study courses with testing administered by a proctor.

Those working to obtain certification must fit into one of the following two categories: advisor or technician.

ABYC defines advisors as “people who work within the marine service sector that desire an ABYC certification but do not physically work on boats performing repairs.” In order to be granted certification, an advisor must receive a passing score on the certification exam. Certifications are valid for five years. If an advisor wants to become re-certified, they must receive a passing score on their re-certification exam and show proof of 10 CEUs (Continuing Education Units).

Technicians are defined as “those that are actually certified to perform trouble-shooting, repairs and equipment installations on boats,” (i.e. technicians and installers). In order to be granted certification, a technician must receive a passing score on the certification exam and show proof of two years of marine technician/installation work experience via the Work Experience Form. Certifications are valid for five years. If a technician wants to become re-certified, they must receive a passing score on their re-certification exam and show proof of 10 CEUs (Continuing Education Units).

Certified advisors and technicians can earn their CEUs by taking relevant courses at approved higher education institutions or by taking advantage of the ABYC Online Learning portal. There, members are granted free access to a range of multimedia presentations and learning tools that can be used at a students’ chosen pace.

In addition to the in-person, self-study, and online study options, ABYC also offers even more educational opportunities through its Marine League of Schools initiative. The Marine League of School is a special status given to institutions whose instructors are certified and whose curriculum is overseen and developed by ABYC. A current list of these schools is as follows:

Boat builders may not be able to certify an entire vessel, but ABYC does have a program that oversees specific components. The ABYC Certified Component Program “confirms that samples of components fully comply with the current applicable ABYC Standards.” The benefit here is that boat builders can offer customers products that have added integrity in terms of both safety and overall efficacy. Additionally, all boat makers that take part in this program are able to double-check the Council’s Certified Components list, an important register created to heighten industry visibility. The International Marine Certification Institute (IMCI) contracts with ABYC to administer these standards on a global level.

In terms of procedure, component manufacturers can undergo one of two separate testing options, the first one being a review conducted by an IMCI-approved laboratory. The second option requires the component manufacturer’s in-house laboratory to be formally-assessed by ICMI. The manufacturer can begin testing and submit testing reports upon approval.

Below you will find the current ABYC Certified Component Program fees schedule:

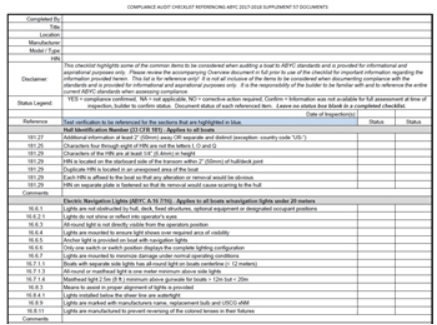

Screenshot via ABYC

Boat builders who are serious about developing and/or reinforcing their own in-house ABYC compliance programs can now take advantage of a streamlined standards checklist, offered by the Council. The ABYC Compliance Audit Tool is an interactive PDF form that serves as an itemized checklist which reflects the major compliance items outlined in Standards and Technical Information Reports for Small Craft.

Currently, the tool is free for business-level ABYC members and available for purchase at $89.95 for all other levels of members.

For more information on ABYC compliance and what it means for boat builders, visit the following resources:

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›