Custom Fabricated Product Identification

Durable, application-specific nameplates, front panels, graphic overlays, signs, and labels.

Solutions for Product Identification, Tracking & Interfaces

Metalphoto of Cincinnati has been a leading full-service manufacturer of durable custom nameplates, panels, overlays, labels and signs for more than 50 years. Our experience is our strength, providing the knowledge and capability to deliver the best solution for your product identification needs.

Industrial Identification Products

Explore our wide range of durable identification products, custom designed for your project, application or organization. Our product development team is on standby to design and build your perfect identification solution.

Request a Nameplate, Front Panel, Label & Tag Evaluation Kit

Request a free evaluation kit today and we will send you a sample kit to test our durable identification products in your own operating environment.

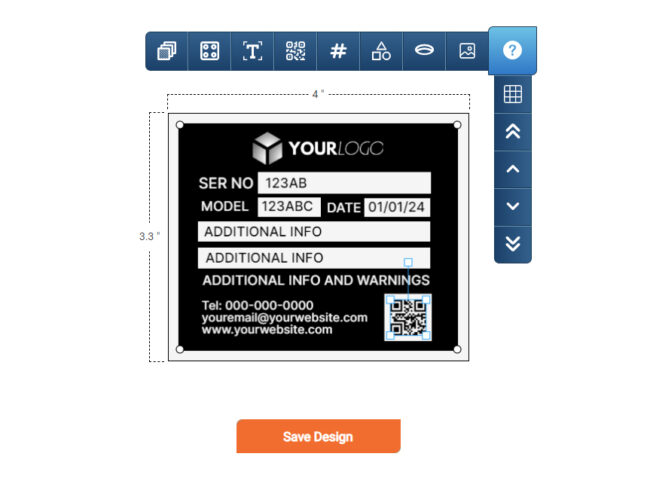

Create Your Own Nameplate, Data Plate, Label, or Front Panel Design Online

The MPC Nameplate Designer is an online tool that you can use to easily create a design for any piece of identification, including nameplates, data plates, warning labels, asset tracking labels, control panel faceplates, overlays and signs. Load a starting template and edit the elements to your specifications, or start from scratch and build your design. Using this designer, you can set the dimensions, material, and add adhesive backing to your identification piece, and then add holes, cutouts, text, serial numbers, bar codes or QR codes, shapes, and even images and photos to your design. Once the design is complete, you can save a PDF print of the design to download and share.

What Do Our Customers Think?

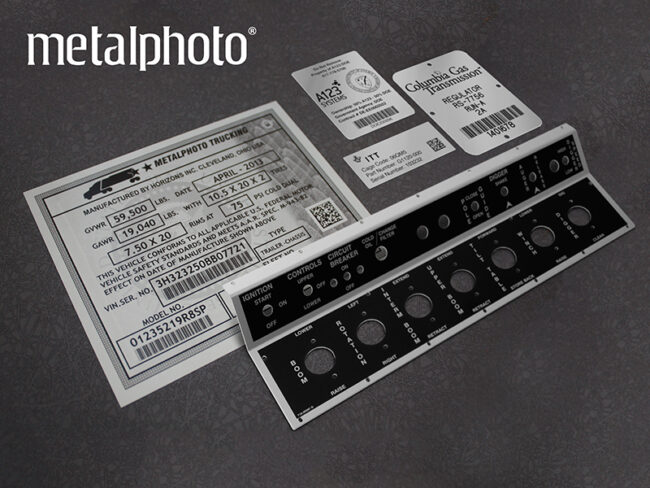

Metalphoto® for Unmatched Durability and Graphic Capabilities

Our company name comes from Metalphoto photographic anodized aluminum, a proprietary metal substrate that gives our identification products unmatched durability and graphics capabilities. Metalphoto’s 3556 dpi, photographic resolution image offers graphic capabilities that other materials and printing methods simply cannot achieve. Because the material is photographically imaged sub-surface rather than printed or painted or etched or engraved, the image combines photo quality capabilites with superior resistance to damage and degradation, even in extreme outdoor environments.

IUID Environmental Survivability Testing Proves Metalphoto’s Superior Durability

The National Association of Graphic and Product Identification Manufacturers (GPI) Industry Standards and Practices Manual identifies Metalphoto photosensitive anodized aluminum as the most durable printed aluminum substrate available, and it has been trusted by defense, military, and government organizations for over 50 years. It’s sub-surface image gives a Metalphoto part an outdoor life of over 20 years, and makes it extremely resistant to damage or degradation, even in the harshest environments and conditions. Read how in a survivability study conducted by the US Navy, Metalphoto outperformed the other 72 materials evalutated across 38 simulated environment durablity tests.

We Provide Solutions for a Wide Range of Industries

Our uniquely durable identification products can help solve industry specific challenges. Discover more identification and interface solutions designed for assets in your industry.

No Minimum Quantity, Get A Quote for Any Size Job

We have no minimum piece requirement. Our minimum production run is $400 per part number, excluding set-up fees/tooling. Contact us regarding your project.

Great First Experience for A New Product Part

This was my first experience with Metalphoto of Cincinnati, MPC. End to end, a great experience. I had a custom stainless-steel plate made for a new product offering. Great communication, fast correction of design on first draft and met their delivery commitment. I will definitely be doing future business with MPC.

20 Years with No Problems

LeBlond Ltd. has been using Metalphoto of Cincinnati for at least 20 years with no problems. I never worry about the quality of product. We always receive competitive pricing and on-time delivery.

ISO 9001:2015 Certified

Metalphoto of Cincinnati has earned ISO 9001:2015 certification from Perry Johnson Registrars. ISO 9000 is a series of quality management systems standards created by the International Organization for Standardization (ISO), a federation of 162 member countries based in Geneva, Switzerland. The American National Standards Institute (ANSI) is the member body representing the United States.

ITAR Compliant Identification Products

Ensuring compliance with the International Traffic in Arms Regulations (ITAR) is a paramount commitment for the Horizons Incorporated companies. As a global leader in identification and automatic data capture solutions, we recognize the critical importance of safeguarding sensitive information related to defense and security. Our unwavering dedication to ITAR compliance is demonstrated through stringent internal processes, comprehensive training for our employees, and robust security measures in handling controlled technical data. By adhering to ITAR regulations, we guarantee that our products, services, and partnerships are in full alignment with the highest standards of national and international security, fostering trust among our clients and partners. Our steadfast ITAR compliance not only exemplifies our responsibility as a global player but also reinforces our dedication to the protection of sensitive information and the preservation of national security on a global scale.

Discover Key Insights for Product Identification

Explore our case studies, blog, buyer’s guides, specification sheets and more — and learn more about the complexities of identifying your assets

Create The Ideal Solution For Your Product Identification Needs

If you’re having trouble finding the ideal identification solution for your project or application, build it with Metalphoto of Cincinnati. Talk with our experienced sales engineers today.