Polycarbonate is a popular type of thermoplastic that is used to fabricate a number of products we use every day. It’s one of the main materials found in eyeglasses, digital media discs, and auto parts due to its light weight and excellent durability under normal conditions. Since high precision graphics can be printed onto polycarbonate, It’s also often used to make signs, labels, overlays, and nameplates.

With high mechanical strength and excellent optical clarity, polycarbonate panels have become widely used in a number of applications. In this post, we’ll review the types of polycarbonate panels that are available, how they are used, and a few important things to keep in mind before you make a purchase. With proper planning, you can select the perfect polycarbonate panel for your needs.

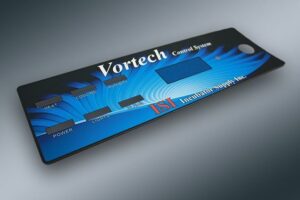

There are two main types of polycarbonate panel products. The first is the polycarbonate overlay, which contains graphics printed onto a molded polycarbonate substrate. These overlays can be purchased directly and installed onto an existing panel that simply needs a new face.

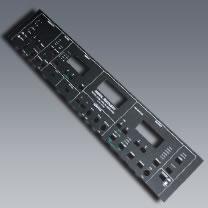

Another option is to purchase a complete 2-part polycarbonate panel that includes the overlay mounted to an identically shaped back panel made of aluminum or stainless steel. The complete panel can be installed directly on equipment to replace an old panel or as a new covering for a custom application.

Polycarbonate has some performance characteristics that make it an excellent material for fabricating equipment panels. When considering polycarbonate for your panel application, it is important to review these properties to see if they match your requirements.

Polycarbonate panels are used in many commercial and consumer applications. One of the main reasons for their popularity is the seamless look that a polycarbonate overlay can bring to any panel surface. With multiple options for the surface texture, including a gloss or matte finish, polycarbonate panels are a versatile option. A few of the most popular applications include:

As you can see, polycarbonate panels are used on equipment that must maintain a nice aesthetic combined with performance and precision. When considering a polycarbonate panel for your application, it’s also helpful to review the many customization options for designing a unique panel overlay to match the overall aesthetic of your device or equipment.

When customizing polycarbonate panels, customers must first determine whether they require an overlay or two-part panel construction. As mentioned above, this decision is usually based on whether a suitable panel surface is present. From there, customers can choose a custom thickness for the polycarbonate substrate and which size or unique shapes may be required. There are many standard sizes available with customizations that can meet just about any need. Experienced manufacturers, such as Metalphoto of Cincinnati, offer design support and expert guidance to help you select the ideal options and design elements for your application.

A polycarbonate overlay or two-part panel can be attached using a durable adhesive or using machined holes on the surface for mechanical attachment. You can also select between a gloss, matte, or textured velvet surface finish. The options for custom graphics are nearly limitless and include unique design elements, custom fonts, and the ability to incorporate a company logo and desired colors. Printing is done with either a digital or screen-printing process, and the printing is done on the second layer to ensure greater durability.

Choosing a polycarbonate overlay or panel doesn’t need to be a complicated process. By working with a trusted partner experienced in designing and manufacturing custom polycarbonate panels and exploring all the options available, you can select the perfect design and form factor for your needs. Polycarbonate is a versatile material used to create panel overlays that have a professional and pleasing look. It remains one of the best choices for custom plastic high-precision panels.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›