How to Properly Label Machines and Equipment in the Laboratory

Properly labeling equipment and machines in a lab is one of the most important tasks in demonstrating good laboratory practices (GLP). A research laboratory might have several experiments in progress at the same time, while a single analytical lab may be processing hundreds or even thousands of samples in a given week. In these environments, equipment is often shared among many scientists and technicians based on their needs on any given day. As you can imagine, tracking all of this work requires structured and reliable systems.

Traceability is the hallmark of a well-run lab and having reliable records ensures that data can be properly analyzed and verified. In many sectors, such as the pharmaceutical and medical industries, there are also extensive regulations that impact laboratory practices and help protect consumers, workers, and the general public. Properly labeling your lab equipment is not only necessary for compliance but also has some great benefits, including the ability to:

In this post, we’ll review a few important actions that you can take to ensure that your laboratory machines and equipment are properly labeled. While requirements may differ between labs, these general practices are a good way to verify if you are on the right track in setting up your own laboratory equipment labeling system.

Most labs have a Laboratory Information Management System (LIMS) or similar program to help track and manage all equipment, samples, safety data sheets (SDS), and testing machines at that location. To streamline data entry, labs should utilize asset labels and tags that include barcodes. Most barcode labels can support a number of different barcode symbologies and since each barcode has a unique identifier, it is easy for researchers and techs to identify an asset, such as testing machines, with a simple barcode scan and enter information into a central system about its use or maintenance. This reduces the need for manual data entry and provides an additional layer of tracking in addition to equipment serial numbers.

When implementing a lab equipment labeling procedure, it’s crucial to standardize the formats for any information that will be tracked. This includes data such as date formatting, equipment ID numbers, naming conventions, and locations. Having different formats between labels can cause confusion and make information more difficult to trace. Choosing a set number of characters and a standardized data format makes it much easier to update tags and transfer equipment between different locations you are managing. You may also find that creating label templates is helpful so that you have an easy reference whenever new tags are required.

Most laboratories use a variety of solvents such as methanol and isopropanol for cleaning, and these can easily degrade the face of a simple printed label. There may also be additional acidic and caustic materials present in a lab that could damage labels if spilled. Understanding these potential hazards, in addition to sources of abrasion or other extreme conditions, will help you choose a label substrate material that is best suited for your particular lab environment.

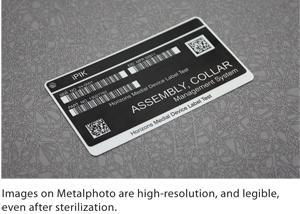

Metalphoto® photosensitive anodized aluminum labels are commonly used in laboratories and medical facilities due to their bacterial resistance, ability to withstand frequent cleaning, abrasion, and chemical exposure. In fact, Metalphoto® photosensitive anodized aluminum was tested to ANSI/AAMI ST79 steam sterilization and sterility assurance standards. For testing machines and other lab equipment that must undergo repeated sanitation cycles, durable labels are a must.

Labels can be added to equipment, but they won’t serve much of a purpose if they are not referenced by scientists, technicians, and other laboratory personnel. Protocols are necessary for most lab practices and labeling should be no different. It’s helpful to have a written labeling procedure that your team can reference with clear instructions for the most important tasks. For example, as soon as any new equipment is brought into the lab it should be labeled and placed in a proper location.

Failing to adhere to your standardized labeling plan could lead to testing machines going out of calibration or difficulty tracking the status of each item. For testing machines in particular, it’s vital to document the specific testing machines used for analysis to trace issues should a machine be found to be out of calibration.

How you choose to label your machines and equipment is just one part of an overall lab safety and communication plan. There are many other notifications that are present in modern labs including safety signs, hazard labels, and compliance tags. To avoid confusion for lab workers, every laboratory should review existing signs and labels periodically to make sure that each one is communicating necessary information, such as identifying a biohazard or x-ray radiation.

Properly labeling testing machines and equipment in the laboratory is an important process and one that should follow a set procedure. By following these best practices, you can ensure that your testing machines and other laboratory equipment are properly maintained, compliant, and in excellent working condition. With durable labeling options available that can withstand frequent cleaning and other laboratory environmental conditions, you can find the perfect solution for your unique lab requirements.

Our sales engineers are experts in automatic asset tracking, tagging and identification,a nd can answer all your questions. Get in touch now.

Lets Talk ›